Essential Materials for Rigid-Flex PCBs: Everything You Need to Know

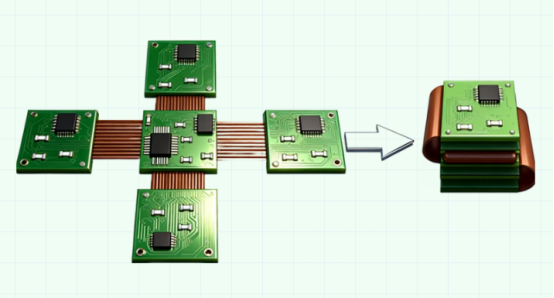

Rigid-Flex PCBs are a hybrid of rigid and flexible printed circuit boards, combining the best features of both. These boards offer the structural stability of rigid circuits with the flexibility of bending, twisting, and conforming to various shapes. This unique design makes Rigid-Flex PCBs essential for applications where space, durability, and adaptability are crucial, enabling advanced functionality in compact electronic devices.

The performance of Rigid-Flex PCBs heavily depends on the materials used in their construction. High-quality materials ensure the boards can handle environmental stress, temperature fluctuations, and mechanical pressure, all while maintaining electrical conductivity and flexibility. Materials like polyimide (PI), known for its flexibility and heat resistance, and copper, which ensures efficient electrical flow, are key to the board's success. The choice of these materials is vital, as they directly affect the board's reliability, longevity, and ability to function in a wide range of applications. In short, the right materials are essential for optimizing the performance and durability of Rigid-Flex PCBs in today's advanced electronic devices.

Core Materials for Rigid-Flex PCBs

Rigid-Flex PCBs rely on a combination of different materials to ensure flexibility, durability, and performance in a wide range of applications. Each material plays a crucial role in the PCB's ability to withstand environmental stress and maintain electrical integrity. Below is an overview of the key materials used in rigid-flex PCBs:

Base Materials

Flexible Copper Clad Laminate (FCCL)

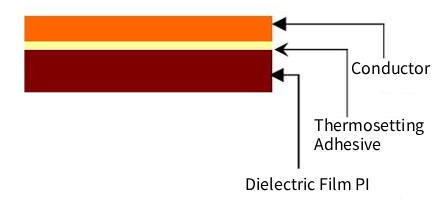

FCCL forms the foundation of flexible circuits, combining copper with a flexible base material. The two most common base materials for FCCL are Polyimide (PI) and Polyester (PET).

Polyimide (PI) (Kapton)

Polyimide is known for its excellent flexibility, high-temperature resistance, and good tear resistance. It is widely used in applications where the PCB must endure mechanical stress and high temperatures. However, PI materials have relatively high moisture absorption, which can cause dimensional changes. Common thicknesses for Polyimide-based FCCL are 12.5 µm, 20 µm, 25 µm, 50 µm, and 75 µm. This makes it suitable for high-performance applications such as aerospace, automotive, and consumer electronics.

Polyester is a more cost-effective option compared to Polyimide. It offers good flexibility, but it is not suitable for high-temperature environments, as its heat resistance is limited. Polyester has lower moisture absorption, making it more stable in humid conditions. However, it has lower tear resistance compared to Polyimide. Common thicknesses for PET-based FCCL are 25 µm, 50 µm, and 75 µm.

Dielectric Substrates

Polyimide (PI)

Polyimide is the most common dielectric material used in rigid-flex PCBs. It provides excellent heat resistance, with a long-term operating temperature of up to 260°C and short-term resistance to temperatures above 400°C. Polyimide also has excellent mechanical and electrical properties, making it ideal for demanding applications in electronics. However, due to its high moisture absorption, the production environment must be carefully controlled to prevent dimensional changes during manufacturing.

Polyester (PET)

Polyester-based dielectric substrates are also used in flexible PCBs, offering good mechanical strength and electrical properties at lower temperatures. However, PET is less heat-resistant compared to Polyimide, making it unsuitable for high-temperature soldering processes (such as lead-free soldering). Its resistance to moisture and dimensional stability make it a good option for low-temperature applications where flexibility is still a priority.

Cover Layers

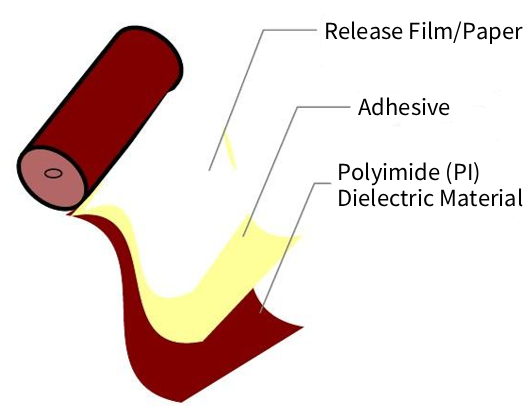

Polyimide (PI) Cover Layer

Polyimide is commonly used for the cover layer in rigid-flex PCBs. It offers high flexibility and excellent thermal resistance, making it ideal for protecting the circuits from moisture, dust, and other contaminants. PI cover layers also help prevent solder from bridging between the traces. Thicknesses typically range from 12.5 µm to 125 µm, depending on the application requirements.

Flexible Solder Mask

A flexible solder mask is often used in flexible PCBs due to its cost-effectiveness and ease of application. While it is cheaper than Polyimide, it offers lower flexibility and is mainly used where precise alignment is needed. It provides a protective layer to prevent short circuits and damage during manufacturing.

Photo-Imaging Covercoat (PLC)

Photo-Imaging covercoats are used for precise alignment of circuits, particularly in high-precision applications. Although it provides excellent accuracy, its flexibility is lower than that of Polyimide. It’s typically used in more specialized applications where precise patterning and fine details are critical.

Conductive Layers

Rolled Annealed Copper

Rolled annealed copper is one of the most commonly used conductive materials in rigid-flex PCBs. It has excellent flexibility, good forming characteristics, and high electrical conductivity, which makes it ideal for flexible circuit designs. The typical thickness of rolled annealed copper ranges from 9 µm to 70 µm, providing the necessary conductivity for various electronic devices.

Electrodeposited Copper

Electrodeposited copper is a more cost-effective option than rolled annealed copper. However, it has slightly inferior electrical performance and is typically used in applications where the conductive requirements are less demanding. It is commonly used to connect different copper layers in multi-layer PCBs. Its typical thickness ranges from 17.5 µm to 70 µm.

Silver Ink

Silver ink is a low-cost material used primarily for electromagnetic shielding or to create connections between copper layers. Although it is not as electrically efficient as copper, it can be used in applications where cost is a major factor and where the circuit does not require high electrical performance. Silver ink is often used in consumer electronics for applications like shielding or low-speed signal paths.

Other Key Materials for Rigid-Flex PCBs

In addition to the core materials, several other specialized materials are essential for the performance, protection, and durability of Rigid-Flex PCBs. These materials include electromagnetic wave protection films, reinforcement materials, and prepreg materials, each playing a critical role in ensuring that the PCB functions optimally in various applications.

Electromagnetic Wave Protection Film

SF-PC5000 Electromagnetic Shielding Film

The SF-PC5000 is an ultra-thin electromagnetic shielding film with a thickness of only 22 µm. This material is specifically designed to provide excellent protection against electromagnetic interference (EMI) in electronic devices. It has outstanding moisture resistance and high dimensional stability, making it ideal for use in lead-free soldering processes. This film is particularly beneficial in applications like slider phones and slim design products, where space-saving and electromagnetic protection are both essential.

Key Features:

Ultra-thin, measuring just 22 µm thick.

High moisture resistance and stability.

Compatible with lead-free reflow soldering.

Suitable for slim devices like sliding mobile phones.

Reinforcement Materials

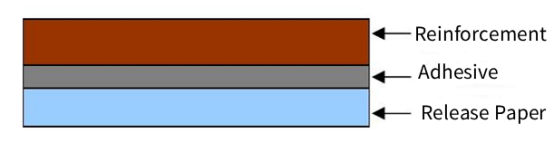

FR4 (Resin Board)

FR4 is a widely used resin-based material that provides reinforcement to specific areas of Rigid-Flex PCBs. It is often added in regions where additional strength is needed, such as areas that require enhanced soldering durability. FR4 helps improve the mechanical strength of the PCB, ensuring it can withstand stress and physical pressure during usage.

Key Uses:

Reinforces specific regions of Rigid-Flex PCBs.

Enhances soldering strength and durability.

Pressure Sensitive Adhesive (PSA)

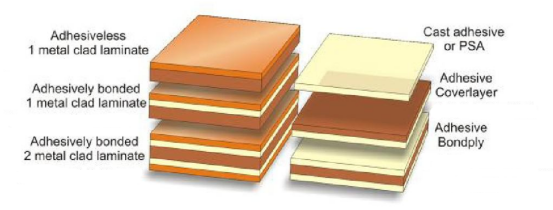

PSA is used to bond the flexible and rigid parts of the PCB together. It provides a secure and stable connection between the flexible circuits and rigid areas, helping to maintain the structural integrity of the PCB during both manufacturing and operation. PSA is especially useful in applications where a strong, reliable bond is necessary without the need for additional heat or pressure.

Key Uses:

Provides strong adhesion between flexible and rigid PCB areas.

Helps ensure stable, long-lasting connections.

Prepreg Materials

No/Low Flow PP (Prepreg Materials)

Prepreg materials, such as low-flow PP, are used in the lamination process of Rigid-Flex PCBs. These materials provide the necessary bonding between different layers of the PCB. Low-flow PP is known for its ability to maintain structural integrity while offering low flow during the lamination process, preventing excessive material movement that could compromise the final product. It is available in various thicknesses, such as 106 (2 mil), 1080 (3.0 mil / 3.5 mil), and 2116 (5.6 mil), depending on the specific application requirements.

Key Uses:

Used in the lamination process of Rigid-Flex PCBs.

Helps maintain structural integrity during manufacturing.

Available in different thicknesses to suit various applications.

Conclusion: The Importance of Rigid-Flex PCB Materials

Choosing the right materials for Rigid-Flex PCBs is crucial for ensuring performance, durability, and cost-efficiency. Different materials impact key factors such as flexibility, heat resistance, and electrical conductivity. For example, Polyimide (PI) offers excellent heat resistance and flexibility, making it ideal for demanding applications, while Polyester (PET) is more cost-effective but less heat-resistant, suitable for less critical use cases.

Material selection should align with the specific needs of the application—whether it's cost-efficiency for consumer electronics or high performance for aerospace systems. High-quality materials ensure reliability, longevity, and optimal function in various environments.

At PCBMASTER, we provide expert manufacturing solutions, offering a range of high-quality materials like Polyimide (PI) and FR4 for diverse Rigid-Flex PCB applications. From design to production, our advanced processes and reliable products meet industry standards, ensuring your PCB designs perform seamlessly in any environment.

FAQs

1. What are the most commonly used materials in Rigid-Flex PCBs?

The most commonly used materials in Rigid-Flex PCBs include Flexible Copper Clad Laminate (FCCL) and Polyimide (PI).

FCCL is typically used as the base material for the flexible part of the Rigid-Flex PCB. It consists of a flexible polymer film, such as Polyimide or Polyester, bonded to a layer of copper foil. The copper foil allows for electrical conductivity, while the flexible film ensures the board can bend without breaking. The advantages of FCCL include high flexibility, good thermal resistance, and strong adhesion properties, making it ideal for flexible circuits that require durability and versatility.

Polyimide (PI), often used in combination with FCCL, is widely favored for its high temperature and mechanical properties. It offers excellent heat resistance, chemical stability, and electrical insulating properties. These attributes make PI ideal for applications where high-performance and reliability are critical, such as in aerospace, automotive, and medical devices.

2. Why is Polyimide (PI) commonly used in Rigid-Flex PCBs?

Polyimide (PI) is a popular material for Rigid-Flex PCBs due to its exceptional heat resistance, flexibility, and electrical performance.

Heat resistance: PI can withstand temperatures up to 260°C in continuous use and over 400°C for short durations, making it ideal for high-temperature environments. This characteristic is critical for industries like aerospace and automotive, where components are exposed to extreme conditions.

Flexibility: PI offers high flexibility, allowing Rigid-Flex PCBs to be bent or folded without breaking. This flexibility is essential in applications where space-saving designs and three-dimensional shapes are needed.

Electrical properties: PI provides excellent electrical insulation, ensuring signal integrity and minimal interference. This makes it suitable for high-speed, high-frequency circuits where electrical performance is crucial.

3. What are the common materials for the conductive layers in Rigid-Flex PCBs?

The conductive layers in Rigid-Flex PCBs are typically made from Rolled Annealed Copper and Electrodeposited Copper.

Rolled Annealed Copper: This material is known for its flexibility, good forming characteristics, and excellent electrical performance. It is typically used for high-quality flexible circuits, where the flexibility and durability of the copper layer are important. However, it is more expensive than electrodeposited copper.

Electrodeposited Copper: This copper is more cost-effective and is commonly used in applications where high electrical performance is not as critical. While it is cheaper, its flexibility and conductivity are generally lower than rolled annealed copper. It is often used for non-flexible layers or for making connections between copper layers in Rigid-Flex PCBs.

4. What is Low-Flow Prepreg (PP), and how does it affect the manufacturing of Rigid-Flex PCBs?

Low-Flow Prepreg (PP), or No/Low Flow PP, is a resin-based material used in the lamination process of Rigid-Flex PCBs. It is typically used to bond different layers of the PCB together without excessive flow of the resin during the heat press process.

Low-flow PP plays a crucial role in controlling resin flow during lamination, ensuring that the layers of the PCB are tightly bonded without excessive material spreading or overflow. This ensures that the final PCB maintains a consistent thickness and structural integrity, particularly in the flexible sections. It also helps to prevent excess resin flow into the vias or copper layers, which can affect the overall quality of the PCB.

5. How does the choice of materials in Rigid-Flex PCBs impact cost?

The choice of materials has a significant impact on the cost and performance balance of Rigid-Flex PCBs.

High-performance materials like Polyimide (PI), rolled annealed copper, and high-grade prepregs tend to increase the overall cost of the PCB due to their superior properties, such as higher heat resistance, better flexibility, and improved electrical performance. These materials are essential for industries where reliability and performance are critical, such as aerospace or medical devices.

On the other hand, cost-effective materials like Polyester (PET) and electrodeposited copper help reduce costs but may sacrifice certain performance characteristics, such as heat resistance and flexibility.

When selecting materials, it is important to strike the right balance between cost and performance, depending on the specific requirements of the application. For example, in consumer electronics, cost-effective options may be acceptable, while in high-end industries, investing in higher-grade materials is often necessary to meet stringent performance and reliability standards.