Aluminum Circuit Board: Superior Thermal Performance & Design Insights

Introduction to Metal Core PCBs

Metal Core PCBs, often referred to as Insulated Metal Substrate (IMS) PCBs, are a specialized type of printed circuit board designed to deliver superior heat dissipation and enhanced thermal conductivity. Unlike conventional PCBs that use fiberglass or plastic substrate, these boards feature a metal core—most commonly an aluminum substrate—which acts as an efficient thermal pathway. This metal core structure allows for the rapid transfer of heat away from critical components, making Metal Core PCBs ideal for high-power applications such as power converters, LED lighting systems, and automotive electronics. The use of an aluminum substrate not only ensures high reliability under high temperatures but also enables the creation of thermally conductive PCBs that maintain performance and longevity in demanding environments. By leveraging the properties of a metal substrate, Metal Core PCBs provide superior heat management, making them a preferred choice for applications where thermal performance is paramount.

Understanding Aluminum Circuit Boards

Aluminum is used in circuit boards due to its heat transfer capabilities, strength, and durability.

Materials used in aluminum PCBs include aluminum and thermally conductive dielectric material.

The substrate material utilized in aluminum circuit boards is primarily metal, which is aluminum. The base material in aluminum circuit boards is typically a metal base, most often aluminum, which provides superior thermal management compared to conventional epoxy glass or conventional rigid PCB substrates.

Common materials for the substrate of aluminum PCBs include aluminum and fiberglass. Aluminum clad and aluminum core designs are popular for their enhanced heat dissipation and durability.

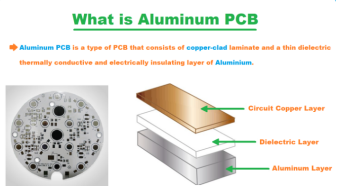

The structure of aluminum PCBs typically includes four layers: a copper foil layer, a dielectric layer, an aluminum base layer, and an aluminum base membrane layer. The key layer is the aluminum base, sometimes referred to as the layer isthe aluminum base, which acts as the primary thermal pathway.

Benefits of Using Aluminum Circuit Boards

Aluminum core PCBs are known for their excellent thermal conductivity, making them a top choice among thermally conductive PCB options. Aluminum circuit boards exhibit superior thermal management by dissipating heat more effectively than standard FR4 boards.

Aluminum circuit boards are recognized for their superior thermal conduction, which enhances device performance.

Due to their effective heat dissipation, aluminum core PCBs are particularly suited for high-power applications.

The aluminum substrates have lower thermal resistance, ensuring consistent operation of critical components.

These boards can include thermal vias that promote better heat flow between layers, optimizing thermal management in high-performance applications.

The mechanical stability of aluminum PCBs contributes to the longevity of electronic components. The use of an aluminum PCB extends the operational lifespan and stability of devices, especially in high-heat applications such as LEDs and power electronics.

Aluminum substrates are highly resistant to wear and tear, which enhances their physical durability.

In automotive electronics, aluminum circuit boards enhance safety and durability in high-temperature areas.

Aluminum circuit boards can handle higher density circuits and larger power levels, making them ideal for high-power applications.

Aluminum PCBs provide a stable thermal platform, which is critical for the performance of power converters.

Aluminum substrates are particularly suited for environments where heat dissipation is critical.

Key Components of Aluminum Circuit Boards

Aluminum PCB structures consist of multiple layers: a copper foil layer, a dielectric layer, and an aluminum base layer. The dielectric layer acts as a thermally conductive layer, often made from advanced thermal materials to optimize heat transfer and provide electrical insulation.

Copper Foil Layer

The copper foil layer in aluminum circuit boards is essential for conducting electricity; a thicker layer allows for handling larger currents. Precise trace copper design is essential for electrical performance, and copper etching is a critical step in manufacturing the copper foil layer. When the copper foil exceeds 3oz, etching requires width compensation to ensure accurate trace dimensions.

Aluminum circuit boards feature a copper foil layer with thicknesses ranging from 1oz to 10oz to adequately manage high current applications.

Dielectric Layer

The dielectric layer in aluminum circuit boards serves the dual purpose of facilitating thermal conductivity while providing electrical insulation. Optimizing the dielectric layer's thermal impedance is crucial for balancing effective heat dissipation and reliable electrical insulation.

The dielectric layer is designed for low thermal resistance, enhancing thermal aging resistance, which is crucial for maintaining optimal performance.

Dielectric layers are made from thermally conductive materials that can handle mechanical and thermal stress, crucial for high-power applications.

Optimizing dielectric thickness and copper weight can lead to impressive thermal performance improvements in aluminum circuit boards.

The material choices for dielectric layers, such as polyimide resin with ceramic fillers, directly impact both performance and manufacturing costs.

Aluminum Base Layer

The aluminum base layer serves as a structural support and is essential for ensuring effective heat dissipation in circuit boards. A protective membrane is often applied to keep the aluminum surface safe from scratching, etching, and high-temperature damage.

The aluminum base layer provides high thermal conductivity, drawing heat away from the circuit.

Aluminum circuit boards retain dimensional stability, changing size by only 2.5% to 3% when subjected to temperature variations from 30°C to 150°C.

Aluminum substrates exhibit higher stability than insulating materials in PCBs.

Overall, the aluminum base layer significantly enhances both heat dissipation and the structural integrity of aluminum circuit boards.

Aluminum PCB Structure

The structure of an aluminum PCB is engineered to maximize both electrical performance and thermal conductivity. At its core, the aluminum PCB is composed of several distinct layers. The topmost copper foil layer is typically thicker than that found in standard PCBs, allowing for greater current carrying capacity and improved durability. Beneath the copper foil layer lies the dielectric layer, which is formulated to be thermally conductive while maintaining low thermal resistance and providing essential electrical insulation. This layer ensures efficient heat transfer from the copper circuitry to the underlying aluminum base. The aluminum base layer, often made from high-quality aluminum alloys, serves as the primary source of thermal conductivity and mechanical strength, supporting the entire PCB structure. In some designs, an additional thin layer of solder mask is applied to protect the aluminum surface from corrosion and environmental damage. An optional aluminum base membrane layer can also be included for added protection and stability. Together, these layers create a robust, thermally conductive, and electrically insulated platform ideal for high-performance electronic applications.

Types of Aluminum Circuit Boards

Aluminum PCBs can be categorized based on their structure, including options like single-sided, double-sided, and multilayer.

Single-sided aluminum circuit boards are typically utilized for simple circuits due to their simplified design.

Double-sided aluminum circuit boards allow for more complex designs and increased circuit density due to their ability to connect components on both sides.

Multilayer aluminum circuit boards provide superior thermal management and are ideal for advanced electronic applications requiring better heat dissipation.

Single-Sided Aluminum PCBs

Single-sided aluminum PCBs are typically utilized in simpler electronic applications due to their straightforward design.

The straightforward design of single-sided aluminum PCBs makes them cost-effective and suitable for less complex circuits.

Single-sided aluminum PCBs are often used in consumer electronics, lighting systems, and other applications that do not require complex circuitry.

Double-Sided Aluminum PCBs

Double-sided aluminum PCBs allow for component placement on both sides, enhancing design complexity and functionality.

These PCBs allow for increased design flexibility, enabling more complex circuit arrangements and better component placement.

Double-sided aluminum PCBs allow for higher component density, which is beneficial for complex circuit designs.

The combination of increased component placement and density makes double-sided aluminum PCBs ideal for sophisticated electronic applications.

Multilayer Aluminum PCBs

Multilayer aluminum PCBs are predominantly used in the high-performance power supply market.

A medical imaging company utilized multilayer aluminum boards to maintain thermal and electrical isolation in compact footprints.

The structure of multilayer aluminum PCBs consists of multiple layers of thermally conductive dielectrics with buried circuitry and blind vias.

A layer of aluminum can form the core of multilayer thermal constructions in aluminum PCBs.

The first step in manufacturing aluminum PCBs involves selecting the appropriate aluminum alloy, which affects thermal conductivity and overall performance.

A downside of multilayer aluminum PCBs compared to single-layer designs is that they are more expensive and less efficient at transferring heat.

Thermal Management Considerations

Effective thermal management is a cornerstone of aluminum PCB design, especially for high-power and high-temperature applications. The metal core, typically an aluminum substrate, is integral to the board’s ability to dissipate heat efficiently. This high thermal conductivity ensures that heat generated by active components is quickly transferred away from sensitive areas, reducing the risk of overheating and thermal failure. The dielectric layer, positioned between the copper circuit layer and the aluminum base, further enhances heat transfer while maintaining electrical insulation. The use of advanced thermal bonding materials and careful optimization of the copper circuit layer layout can significantly improve overall thermal performance. By prioritizing these thermal management strategies, aluminum PCBs are able to deliver superior reliability and extended operational lifespan, even in the most demanding high-power environments.

Layer Aluminum Design

Layer Aluminum Design refers to the strategic arrangement of layers within an aluminum PCB to achieve optimal electrical and thermal performance. Typically, this design includes a copper layer for circuit formation, a dielectric layer for electrical insulation and thermal conductivity, and an aluminum base layer that acts as a heat sink and provides mechanical support. The copper layer is precisely etched to create the desired circuit paths, while the dielectric layer—made from advanced dielectric materials—ensures both high thermal conductivity and robust electrical insulation. The aluminum base, often crafted from specialized aluminum alloys, is essential for dissipating heat and maintaining the structural integrity of the PCB. In multilayer aluminum PCBs, additional copper and dielectric layers are incorporated to accommodate through-hole components and further enhance thermal performance. This layered approach allows for the creation of complex, high-reliability circuits that can handle significant power loads while maintaining excellent thermal management.

Manufacturing Process of Aluminum Circuit Boards

The major manufacturing processes involved in producing aluminum circuit boards include copper etching, solder mask printing, and the mechanical manufacturing process.

Aluminum substrates are suitable for various mechanical processes like drilling, cutting, and punching. The mechanical manufacturing process often utilizes a professional milling cutter for precision, especially in low-volume production.

An aluminum base membrane is used to protect the surface of the aluminum layer from physical damage and chemical etching.

The surfaces of aluminum sheets must be cleaned and treated to ensure proper adhesion during the lamination process. Nearly all aluminum PCBs require careful handling during manufacturing to address challenges such as thick copper foil and mechanical processing.

After lamination, the aluminum boards undergo a drilling process for vias and mounting holes, using specialized equipment to accommodate the metal substrate.

After solder mask printing, it is important to use high-quality solder mask oil to ensure proper adhesion and coverage, particularly over thick copper traces.

Challenges in Manufacturing Aluminum Circuit Boards

Aluminum circuit boards are typically etched using chemical processes to create the desired circuit patterns. The metal base draws heat away from components, which is essential for effective thermal management but also introduces challenges in maintaining structural integrity during manufacturing.

The presence of thick copper foil can complicate solder mask printing on aluminum PCBs.

Achieving a strong bond between the dielectric and aluminum substrate can be difficult due to the smooth surface of aluminum.

Thermal stress from heat generation can lead to warping or stress at solder joints in aluminum PCBs.

Sourcing high-quality aluminum and dielectric materials can present challenges due to supply chain fluctuations.

Circuit Boards Comparison

When comparing different types of circuit boards, aluminum PCBs stand out for their exceptional thermal conductivity and superior heat dissipation, thanks to their metal core and aluminum substrate. Unlike traditional circuit boards that rely on fiberglass or plastic substrates, aluminum PCBs tend to offer greater durability, higher reliability, and a longer operational lifespan—especially in high-power and high-temperature environments. The metal core draws heat away from critical components, making these boards ideal for power electronics, LED lighting, and other demanding applications. While aluminum PCBs can be more expensive and require a more complex manufacturing process than standard PCBs, their benefits—such as high thermal conductivity, superior heat dissipation, and robust performance—often outweigh the drawbacks. By understanding the unique advantages of aluminum PCBs, designers and engineers can select the most suitable circuit board technology for their specific needs, ensuring optimal performance and reliability in their end products.

Applications of Aluminum Circuit Boards

Aluminum circuit boards are commonly applied in high-power systems, including LED lighting, automotive electronics, medical devices, and aerospace. Aluminum core PCBs are especially valued in these industries for their lightweight nature, cost-effectiveness, high durability, and efficient heat dissipation.

The primary applications of aluminum circuit boards include LED and power converting electronics, making them vital in modern technology. Aluminum core PCBs are widely used in household lighting, street lights, and other lighting fixtures due to their efficient heat dissipation and reliability, which help extend the longevity of LED lighting devices.

Industries like automotive, medical, and aerospace are increasingly utilizing aluminum PCBs for their reliability and performance.

High-power LED lighting applications benefit significantly from the thermal management capabilities of aluminum circuit boards.

Multilayer aluminum PCBs are particularly suited for compact devices due to their design that supports high-density interconnections.

The unique structure of aluminum circuit boards allows for advanced designs with higher circuit densities and improved thermal management.

LED Lighting Systems

LED lighting applications benefit significantly from aluminum PCBs due to their superior heat management capabilities.

Single-sided aluminum PCBs are commonly utilized in applications such as LED lighting, power supply circuits, and consumer electronics.

A power LED module manufacturer achieved a significant improvement by utilizing aluminum PCBs, reducing junction temperatures by over 20°C.

The intended application, whether for LED systems or automotive electronics, can dictate the specific type of aluminum circuit board to use.

Automotive Electronics

Aluminum circuit boards provide increased reliability, essential for automotive electronics that face various environmental factors.

The durability of aluminum circuit boards makes them well-suited for harsh automotive conditions, enhancing the lifespan of electronic components.

Aluminum circuit boards excel in thermal management, allowing for effective heat dissipation in high-temperature automotive applications.

By improving reliability and thermal performance, aluminum circuit boards significantly enhance the overall performance of automotive electronics.

Power Converters

In power converters, aluminum PCBs are essential for managing the high power loads while maintaining thermal stability.

Choosing the Right Aluminum Circuit Board for Your Project

Understanding the specific thermal and electrical requirements of your project is crucial for selecting the appropriate aluminum circuit board.

Project environments, such as exposure to high temperatures or humidity, should be assessed to ensure compatibility with the selected aluminum circuit board.

The thickness of the copper foil used in aluminum circuit boards typically ranges from 1oz to 10oz to support larger current capacities.

Single-sided aluminum PCBs are often utilized in applications where simplicity and cost-effectiveness are key considerations

FAQs

A. What is the core difference between Aluminum-based PCBs and traditional FR4 PCBs?

Q.

·Heat dissipation: Aluminum-based PCBs have much higher thermal conductivity than FR4, enabling rapid heat export, suitable for high-power equipment

·Strength: The aluminum substrate enhances mechanical rigidity, providing stronger resistance to vibration and impact

·Application: Aluminum-based PCBs are often used in LEDs, automotive electronics, etc., while FR4 is suitable for general consumer electronics.

A.What are the main advantages of Aluminum-based PCBs?

Q.

·Efficient heat dissipation, lowering component temperature, extending lifespan;

High mechanical strength, adaptable to harsh environments

·Strong current-carrying capacity; thermal expansion coefficient matches components, reducing the risk of solder joint failure.

A.What challenges are faced in manufacturing?

Q.

·The insulation layer tends to crack, requiring optimization of materials and processes;

·Differences in thermal expansion between aluminum and copper may cause solder joint issues

Cost is higher than traditional PCBs; process complexity is greater.

A.How to select a suitable Aluminum-based PCB?

Q.

·For high-power scenarios, choose products with thermal conductivity ≥2.0W/(m·K);

·For high-voltage environments, a thicker insulation layer is needed (e.g., ≥150μm);

Select the surface finish process (e.g., ENIG, OSP) based on soldering requirements.

Why PCBMASTER: https://www.pcbmaster.com/why

Join US:https://www.pcbmaster.com/login