Applications of Stainless Steel Core PCBs Technological Breakthroughs from New Energy Vehicles to Deep-Sea Equipment

I. Technical Characteristics and Market Positioning of Stainless Steel Core PCBs

According to the latest 2024 report by Prismark, the global metal core PCB market has reached $5.8 billion, with stainless steel-based products surging from 7% in 2020 to 19% of the market share. Its core competitiveness lies in:

1. Extreme Environmental Adaptability

①Tensile Strength: 520 MPa (2× higher than aerospace-grade aluminum)

②Corrosion Resistance Lifespan: 15 years (ASTM G85 acid salt spray test)

③Thermal Resistance: 0.8℃·cm²/W (1mm thickness), 33% lower than aluminum substrates

2. Cost-Effectiveness Turning Point

①SUS304 Substrate Price in 2023: Reduced to $85/m² (42% drop since 2018)

②Lifecycle Cost: 28% lower than aluminum substrates (Tsinghua Shenzhen International Graduate School calculation)

II. New Energy Vehicle E-Systems: Solving Thermal Runaway Challenges

2.1 Motor Controller Case Study

A Leading Automotive Manufacturer’s 800V High-Voltage Platform Project:

①Operating Temperature: Sustained 150℃ (traditional solutions max at 120℃)

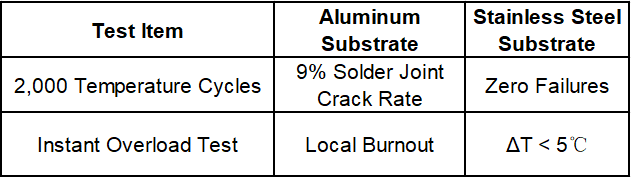

②Thermal Stress Test Results:

Key Design Innovations:

1. Direct contact between power modules and substrate via window openings (65% reduction in thermal resistance)

2. Nano-silver sintering process (thermal conductivity: 250 W/mK)

3. Substrate thickness optimized to 0.8mm (30% weight reduction)

2.2 Onboard Charger (OBC) Breakthrough

Mass Production Data for a 22kW OBC:

①Power Density: 3.2 kW/L (industry average: 2.5 kW/L)

②Full-Load Temperature Rise: 42℃ → 29℃ (ambient temperature: 25℃)

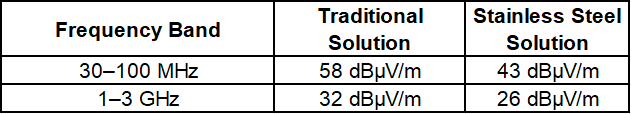

③EMI Radiation Levels:

III. Industrial Equipment: Reliability Revolution in Heavy-Duty Scenarios

3.1 Industrial Robot Servo Drivers

An International Brand’s Sixth-Axis Joint Module:

①Vibration Resistance: Passed IEC 60068-2-64 20Grms test

②Protection Rating: IP67 (direct exposure to cutting fluid)

③MTBF: Increased from 30,000 to 80,000 hours

Key Innovations:

Sandwich Structure Design (Figure 1):

①Top Layer: 0.3mm PI copper-clad laminate (signal layer)

②Middle Layer: 1.0mm SUS304 (thermal conduction + structural support)

③Bottom Layer: 0.2mm graphene coating (EMI shielding)

Laser Microvia Technology: Aperture <50μm, positional accuracy ±5μm

3.2 Photovoltaic Inverter Cooling Solutions

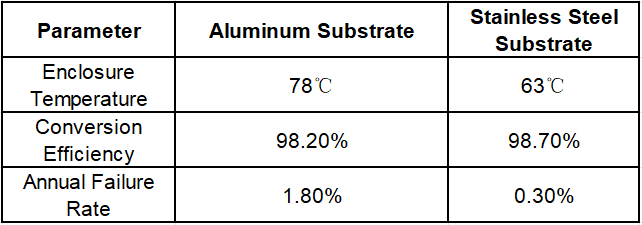

Comparison Test at a 5MW Power Plant (Ambient Temperature: 45℃):

Integrated Fin Design (Figure 2):

40% increase in heat dissipation area with only 15% weight gain

IV. Marine Engineering: Breaking Deep-Sea Corrosion Barriers

4.1 Submarine Cable Repeaters

A Transoceanic Communication Project (Depth: 5,500m):

Pressure Test: Withstood 100 MPa hydrostatic pressure (equivalent to 10,000m depth)

Anti-Corrosion System:

①Base Material: SUS316L (Mo content: 2.5%)

②Coating: PEEK + nano-ceramic composite layer (total thickness: 80μm)

Field Data:

①10-year corrosion rate <0.03mm/year (ASTM G59 standard)

②Maintenance cycle extended from 18 months to 5 years

4.2 Offshore Wind Power Converters

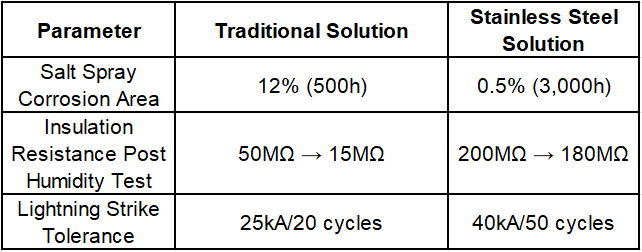

Comparison Data for an 8MW Wind Turbine:

V. Military & Aerospace: Extreme Environment Validation

5.1 Satellite Power Controllers

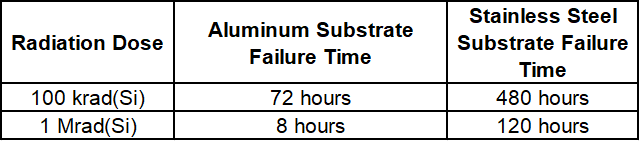

A Low-Earth Orbit Satellite Project:

Thermal Cycling Range: -180℃ to +150℃ (vacuum environment)

Radiation Resistance:

Laser Direct Structuring (LDS) Technology:

Line precision ±3μm, eliminating side etching issues in traditional processes

5.2 Armored Vehicle Electronic Systems

Field Tests for a Main Battle Tank:

Impact Resistance: Passed MIL-STD-810H 40g/11ms test

Environmental Protection:

①Mold Resistance: Grade 0 (GB/T 2423.16)

②Salt Spray Resistance: >3,000 hours without corrosion

③Dust Protection: IP6K9K rating

VI. Cost Control and Mass Production Practices

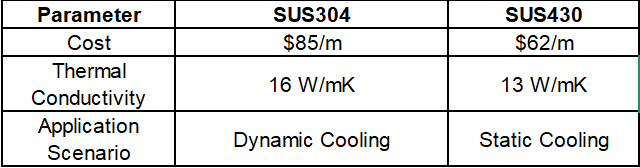

6.1 Material Innovation for Cost Reduction

SUS430 vs. SUS304 Comparison:

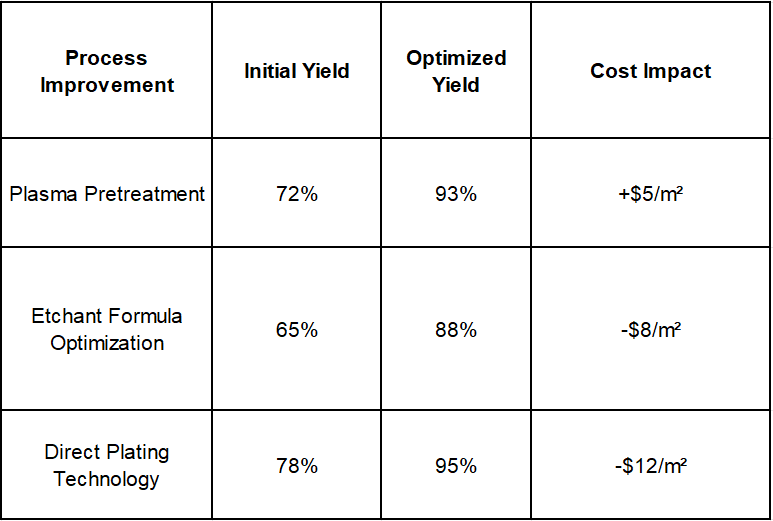

6.2 Process Optimization for Yield Improvement

Production Data from a Leading Manufacturer:

Technological Outlook: Next-Generation Stainless Steel Core PCB Trends

1. Ultra-Thin Technology: 0.3mm-thick substrates validated for automotive standards

2. Smart Thermal Management: Integrated temperature-sensing films (±0.5℃ accuracy)

3. Green Manufacturing: Etchant waste recovery rate increased to 98%

(Data sources: IPC, Fraunhofer Institute, and field reports from industry leaders. Case details are technically desensitized.)

Future Market Prospects of Stainless Steel Core PCBs