Aluminum vs. Copper for Metal Core PCBs: Key Differences

Metal core PCBs (MCPCBs) are a specialized type of printed circuit board, where the core material is metal instead of the traditional fiberglass or resin. The main advantage of MCPCBs lies in their exceptional heat dissipation capabilities, effectively transferring the heat generated by electronic components, which enhances the reliability and performance of the board. Typically, the metal substrates used in MCPCBs are made of aluminum or copper. Aluminum is widely used in consumer electronics due to its lightweight and cost-effective nature, while copper is preferred for high-end electronics due to its superior thermal conductivity. While both materials have their benefits, choosing the right metal substrate involves more than just considering heat dissipation—it also requires evaluating overall system performance, cost control, and manufacturing feasibility. This article will dive into the key differences between aluminum and copper substrates in metal core PCBs, helping you make more informed decisions in your design process.

Why Choose Aluminum for Metal Core PCBs?

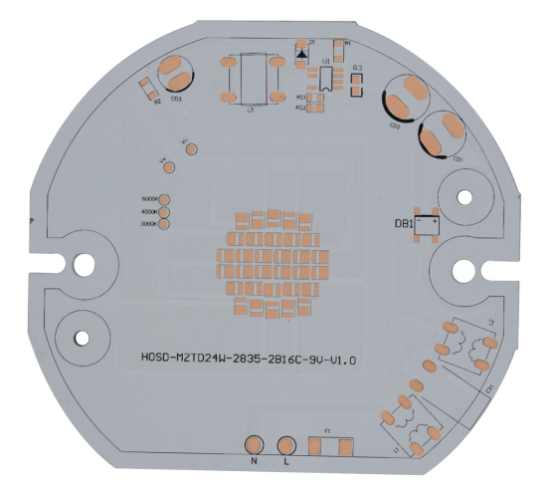

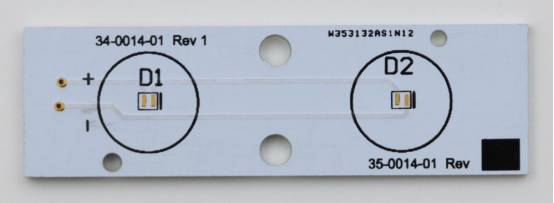

Aluminum is a popular choice for metal core PCBs due to its lightweight, cost-effective nature, and good thermal conductivity. It's ideal for mid-range applications like LED lighting and automotive electronics, offering reliable heat dissipation at a lower cost.

1. What are the key advantages of aluminum as a substrate for Metal Core PCBs?

Lightweight properties and ease of processing:

Aluminum is one of the lightest metals used in metal core PCBs, making it ideal for applications where weight is a critical factor. This makes aluminum-based PCBs especially popular in consumer electronics and automotive systems, where reducing weight can improve energy efficiency and reduce overall device size. Moreover, aluminum is easier to handle and process during manufacturing compared to heavier metals, which can lower production costs and shorten lead times.

Cost-effectiveness compared to other substrates:

Compared to copper and other metals, aluminum is relatively inexpensive. This affordability makes aluminum-based PCBs a popular choice for mass-market applications where cost-efficiency is essential. For example, in products like LED lighting and power supplies, where large volumes are needed, aluminum allows for significant savings without sacrificing much performance.

Superior thermal conductivity for mid-range applications:

Aluminum offers good thermal conductivity, up to 237 W/m·K. While not as high as copper, this level of heat dissipation is sufficient for most mid-range power applications, such as LED lighting or low-power automotive electronics. Aluminum's thermal conductivity helps to prevent overheating of components by transferring heat away from the electronic parts, thus improving the longevity and reliability of the system.

2. When is aluminum the preferred choice for MCPCBs?

Best for low to mid-power applications like LED lighting, power supplies, and automotive electronics:

Aluminum is an excellent choice when heat dissipation is important but extreme thermal management isn't necessary. It’s particularly useful in applications like LED lighting, where the components generate heat but not at the levels seen in high-power systems. Similarly, aluminum-based PCBs are commonly used in power supplies, where the demand for thermal management is moderate but still important to ensure efficiency and longevity.

Example: LED streetlights vs. high-performance computing systems:

Aluminum is a preferred choice for applications like LED streetlights, where moderate heat dissipation is required and the cost of copper might be prohibitive. On the other hand, for high-performance computing systems, where very high levels of heat are produced, copper-based PCBs might be better suited due to their superior thermal conductivity. Aluminum’s role in low- and mid-power applications makes it an ideal substrate for devices that do not experience extreme thermal loads but still need effective heat management.

3. How does aluminum affect the performance and longevity of MCPCBs?

Long-term durability in moderate thermal cycling:

Aluminum-based MCPCBs can handle moderate thermal cycling well. This means that as the electronic components heat up and cool down, the aluminum substrate can expand and contract without cracking or warping. This durability is crucial in applications where devices will undergo frequent temperature changes, such as in automotive electronics or industrial lighting. However, aluminum is not ideal for extreme temperature fluctuations, where copper might perform better due to its stronger resistance to thermal stress.

Resistance to corrosion and oxidation:

One of aluminum’s significant advantages is its resistance to corrosion and oxidation. When exposed to air, aluminum naturally forms a protective oxide layer, which shields the metal from further degradation. This makes aluminum MCPCBs suitable for outdoor applications or environments with moisture, as they are less likely to deteriorate over time. This property is especially beneficial for applications like outdoor LED lighting or automotive systems, where components are exposed to harsh conditions.

Why Choose Copper for Metal Core PCBs?

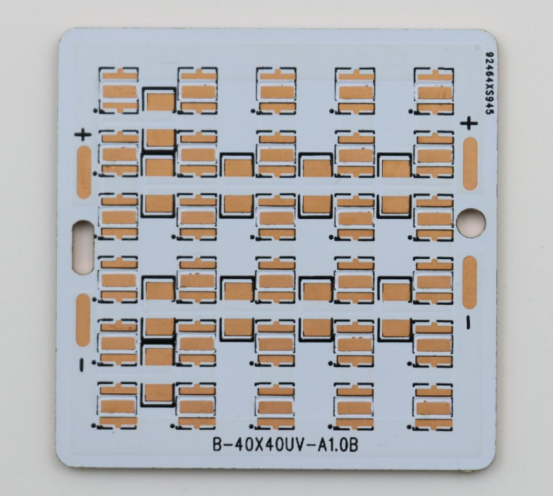

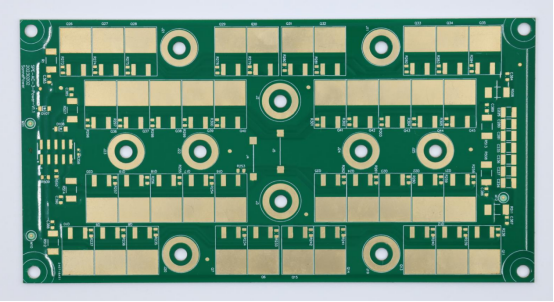

Copper is the top choice for metal core PCBs when high performance and efficient heat dissipation are essential. With its superior thermal conductivity and ability to handle high power densities, copper excels in demanding applications like power electronics, RF circuits, and aerospace technology.

1. What are the key advantages of copper as a substrate for Metal Core PCBs?

Higher thermal conductivity compared to aluminum:

Copper is known for its superior thermal conductivity, approximately twice that of aluminum. This means copper-based MCPCBs can handle heat much more effectively, making them ideal for applications where heat dissipation is crucial. Copper can quickly absorb and transfer heat away from sensitive components, preventing overheating and ensuring the electronics function at optimal temperatures. This advantage is particularly important in high-power applications where maintaining temperature control is essential.

Ability to handle higher power densities and extreme heat dissipation needs:

Copper substrates are better suited for high-power applications due to their ability to manage higher power densities. In devices that generate significant heat, such as high-end power converters, RF amplifiers, and certain industrial machinery, copper's superior heat transfer properties help prevent the risk of component failure. Copper MCPCBs are built to support extreme heat dissipation demands without compromising on performance, ensuring longer-lasting, reliable operation even in harsh environments.

2. When is copper the preferred choice for MCPCBs?

Ideal for high-performance applications, such as high-frequency RF circuits, military, aerospace, and power electronics:

Copper-based MCPCBs are often the preferred choice in applications requiring high performance, such as high-frequency RF circuits, military electronics, and aerospace technology. In these sectors, the ability to handle high power levels and extreme temperatures is critical. For example, copper is commonly used in communication systems, radar technologies, and aerospace avionics, where performance, heat management, and reliability are non-negotiable.

Example: High-end power converters and RF amplifiers:

Copper’s thermal efficiency makes it an essential material for high-end power converters and RF amplifiers. These devices generate significant amounts of heat, and copper MCPCBs provide the thermal management required to ensure their safe and efficient operation. For instance, in power conversion systems, copper helps to keep the components cool under high loads, reducing the risk of thermal damage and extending the device's operational lifespan.

3. How does copper impact the reliability and performance of MCPCBs?

Enhanced heat dissipation for high-power applications:

The ability of copper to rapidly conduct heat away from high-power components significantly enhances the reliability of MCPCBs in demanding applications. As copper efficiently dissipates heat, it reduces the chances of thermal stress, which can lead to component failure, signal degradation, or reduced lifespan. In industries like power electronics, where maintaining precise temperature control is crucial, copper ensures that devices perform optimally under heavy load conditions.

Longer lifespan under extreme conditions (e.g., high temperatures and voltage):

Copper’s robust thermal properties and excellent electrical conductivity make it highly reliable in extreme conditions, such as high temperatures and high voltage environments. Copper MCPCBs are more resilient to long-term thermal cycling and electrical stress, resulting in a longer operational life. This makes copper the material of choice for electronics that must operate continuously under intense conditions, such as military and aerospace equipment, which must endure extreme temperature fluctuations and high electrical loads without compromising performance.

What Are the Key Differences Between Aluminum and Copper Substrates?

When choosing between aluminum and copper for metal core PCBs, the key differences lie in their thermal conductivity, cost, mechanical strength, and weight. While copper excels in heat dissipation and durability, aluminum offers a more cost-effective, lightweight solution for less demanding applications.

1. Thermal Conductivity: How Do Aluminum and Copper Compare?

Thermal conductivity refers to a material's ability to conduct heat. Copper, with its higher thermal conductivity, efficiently dissipates heat away from components, making it ideal for applications that require rapid heat management, like power electronics or RF circuits. On the other hand, aluminum, with its lower thermal conductivity, is well-suited for mid-range applications where heat dissipation is important but not as critical. For example, aluminum is often used in LED lighting, where high heat dissipation is needed, but not to the extreme levels required in power conversion systems.

Impact on Heat Management:

In applications where excessive heat can damage components, copper is the go-to material. For high-power devices like RF amplifiers or high-end power converters, copper ensures that heat is effectively absorbed and transferred, protecting the system’s performance and longevity. For less demanding tasks, like automotive electronics or consumer LED lighting, aluminum provides sufficient heat management at a lower cost.

2. Cost Comparison: Which Substrate is More Economical?

Copper is more expensive than aluminum, both in terms of raw material cost and the manufacturing process. While copper provides superior thermal conductivity, aluminum offers a more budget-friendly solution, which is why it’s commonly used in mass-produced consumer electronics like LED lights and power supplies.

Cost Impact on Large-Scale Manufacturing:

For large-scale production, especially in industries like automotive and consumer electronics, the cost difference becomes significant. Using aluminum for MCPCBs reduces the overall production cost, making it an attractive choice when cost control is crucial. Copper, while more expensive, is often selected in specialized applications where high thermal performance is non-negotiable, despite the higher manufacturing cost.

3. Mechanical Strength: How Does Aluminum vs. Copper Compare in Terms of Durability?

When it comes to durability, copper outperforms aluminum in terms of mechanical strength. Copper is less prone to deformation under stress, bending, or impact. This makes copper MCPCBs ideal for applications in military and aerospace systems, where the components need to withstand harsh conditions, including vibration and mechanical forces.

Strength Advantage in High-Stress Environments:

In comparison, aluminum, while strong enough for many applications, is more susceptible to damage under extreme stress or impact. For example, aluminum might be used in LED lighting or consumer electronics, where mechanical stress is minimal, but copper is the material of choice in high-performance computing or power electronics, where components experience more rigorous mechanical forces and need a more durable substrate.

4. Weight Considerations: How Does the Substrate Material Impact Product Design?

Aluminum is about one-third the weight of copper, which makes it a more favorable choice for lightweight applications. For example, in automotive electronics or portable consumer devices, reducing weight is crucial for performance and efficiency. Aluminum's lightweight properties make it easier to design compact, efficient products without sacrificing durability.

Impact on Product Design:

In contrast, copper’s weight can be a disadvantage in applications where reducing the overall mass of the product is essential. For instance, in aerospace electronics or mobile devices, where every gram counts, aluminum is the preferred choice for MCPCBs. On the other hand, for high-end power converters or RF amplifiers, the weight of copper is not a significant concern because thermal performance outweighs the need for weight savings.

Comparison Table: Aluminum vs. Copper Substrates

Property Aluminum Copper Thermal Conductivity ~237 W/m·K ~401 W/m·K Cost Lower cost Higher cost Mechanical Strength Good, but less durable Stronger, more durable Weight Lighter, ideal for portable designs Heavier, suitable for high-power designs Ideal Applications LED lighting, automotive, power supplies Power electronics, RF circuits, aerospace Performance in Extreme Conditions Adequate, less suitable for high-stress Superior in high-stress and high-temperature environments

How Does Application and Performance Affect Substrate Choice?

The choice of substrate material—aluminum or copper—largely depends on the specific application and performance requirements. Factors like power needs, heat dissipation, space constraints, and the importance of signal integrity all play a role in determining which substrate is best suited for a particular use.

1. What are the key factors influencing the choice of aluminum vs. copper in different applications?

Power Requirements: Copper is ideal for high-power applications due to its superior thermal conductivity, which efficiently manages the higher heat generated by powerful components. For example, in power supplies and high-end power converters, copper ensures the heat is quickly transferred away from sensitive components, maintaining optimal performance.

Heat Dissipation: Copper’s higher thermal conductivity (~401 W/m·K) makes it more suitable for applications where heat needs to be quickly dissipated, like RF amplifiers or military electronics. However, aluminum, with its thermal conductivity (~237 W/m·K), is more cost-effective for applications where moderate heat dissipation is sufficient, such as in LED lighting or consumer electronics.

Space Constraints: Aluminum’s lightweight properties make it a good fit for compact designs, such as in automotive electronics or portable medical devices, where both space and weight are at a premium. Copper is heavier, but it may be used where the performance demands outweigh the need for weight reduction.

Examples from Various Industries:

Consumer Electronics: Aluminum MCPCBs are used in LED lighting and small power supplies, where cost and weight are crucial factors, and heat management needs are moderate.

Automotive: For engine control units (ECUs), aluminum is often preferred due to its lightweight properties, helping reduce overall vehicle weight.

Aerospace: Copper-based MCPCBs are chosen for applications that require the highest thermal management, like radar and communication systems.

Medical Devices: In medical imaging equipment, copper substrates might be preferred for their superior heat dissipation, especially in high-frequency circuits where signal integrity and heat management are both critical.

2. How do aluminum and copper substrates impact signal integrity and high-frequency applications?

Copper’s Superior Conductivity for High-Speed Signal Processing:

Copper’s high electrical conductivity ensures that signals are transmitted quickly and with minimal loss. This makes it the material of choice for high-frequency circuits, such as those found in RF communication and microwave systems, where maintaining signal integrity is crucial. Copper’s low resistance and ability to support high-speed signal processing without significant loss or distortion make it ideal for military and aerospace applications where precise communication is vital.

Aluminum’s Limitations in High-Frequency Circuits:

While aluminum offers good thermal properties, its electrical conductivity is lower than copper's, which can lead to signal loss and degradation in high-frequency applications. For example, in high-speed signal processing applications, such as 5G technology or high-frequency RF circuits, aluminum's resistance can cause unwanted interference or weak signal transmission. As a result, aluminum substrates are typically not used in applications where signal integrity is paramount, such as telecommunications or data centers.

Real-World Examples:

High-Frequency RF Circuits: Copper-based MCPCBs are commonly used in 5G base stations, where signal clarity and speed are essential for seamless communication.

Consumer Electronics: In products like smartphones or tablets, where high-frequency signals are processed, copper ensures efficient data transfer and reduces the risk of interference.

Conclusion

When choosing between aluminum and copper substrates, the decision should be based on your specific needs. If cost, weight, and moderate heat dissipation are important factors, aluminum is the ideal choice for applications like LED lighting and consumer electronics. However, for high-performance systems requiring superior heat management and electrical conductivity—such as power electronics, RF circuits, and aerospace applications—copper is the better option.

At PCBMASTER, we understand the critical role that substrate choice plays in your product's performance. As an experienced PCB supplier, we offer both high-quality aluminum and copper substrates tailored to meet the unique demands of various industries. Whether you're designing for high-speed circuits or energy-efficient devices, PCBMASTER delivers reliable and durable solutions to ensure your projects succeed. Trust us to provide the right material for your next PCB design.

FAQs

1. What is the main difference between aluminum and copper in terms of heat dissipation?

Copper has superior heat dissipation compared to aluminum due to its higher thermal conductivity.

Thermal conductivity refers to how well a material can conduct heat. Copper has a thermal conductivity of around 401 W/m·K, while aluminum’s thermal conductivity is about 237 W/m·K. This means copper is much more efficient at transferring heat away from the components. In high-performance systems like power electronics or RF circuits, copper is the material of choice because it can quickly dissipate heat, preventing overheating and ensuring stable operation. Aluminum, although still effective for heat management, is more suited to applications where heat dissipation is important but not as critical, such as LED lighting or automotive electronics.

2. Is aluminum good for high-performance MCPCBs?

Aluminum is good for mid-range performance MCPCBs but is less effective for high-performance systems, where copper is the better choice.

Aluminum is widely used in applications that don’t require extreme heat dissipation or high electrical conductivity. For example, LED lighting and consumer electronics can benefit from aluminum MCPCBs because they require efficient heat management without demanding high-speed signal processing or handling high power. However, for high-performance MCPCBs, such as those used in power converters or RF amplifiers, copper is better due to its superior thermal and electrical conductivity, which are essential for handling high power and ensuring fast signal transmission.

3. Can aluminum be used in high-power electronics, or is copper always the better choice?

While aluminum can be used in high-power electronics, copper is generally the better choice for applications that require efficient heat dissipation.

Aluminum can be used in high-power electronics, but its lower thermal conductivity (~237 W/m·K) makes it less effective in handling the excessive heat produced by high-power components. For example, in high-power LEDs or power supplies, aluminum may struggle to manage the high levels of heat generated, leading to potential overheating and reduced system performance. Copper, with its superior thermal conductivity (~401 W/m·K), is more suitable for such applications as it can rapidly dissipate heat, thereby preventing thermal damage and ensuring the longevity and efficiency of the components. Therefore, copper is preferred for high-power electronics where efficient heat management is crucial.

4. How do aluminum and copper substrates affect the overall cost of MCPCB production?

Aluminum is generally more cost-effective than copper, making it a preferred choice for mass-market applications.

The cost of aluminum is lower than that of copper, both in terms of raw material price and manufacturing complexity. Aluminum’s lower cost makes it a popular choice for consumer electronics like LED lighting and automotive electronics, where cost control is important. Additionally, aluminum substrates are easier to process, which reduces manufacturing costs. On the other hand, copper is more expensive due to its higher material cost and the more complex processes required for its use in high-performance applications like power converters and RF circuits. While copper's higher performance justifies its higher cost in specialized applications, aluminum remains the more economical choice for projects with less stringent heat management needs.

5. Which material is more durable—aluminum or copper—for long-term use in electronics?

Copper is more durable in high-stress environments, but aluminum has better corrosion resistance and works well in less demanding applications.

Aluminum naturally forms a protective oxide layer when exposed to air, giving it excellent corrosion resistance and making it ideal for environments with moisture, such as outdoor lighting or automotive applications. However, aluminum is more prone to mechanical stress, bending, or impact compared to copper. Copper, on the other hand, is more durable and resistant to mechanical stress, making it ideal for high-performance electronics that experience more rigorous conditions, such as in military or aerospace applications. However, copper is more susceptible to oxidation and requires coatings or treatments to prevent corrosion in moisture-prone environments. Overall, copper is more durable for high-stress, high-temperature environments, while aluminum excels in corrosion resistance for less demanding applications.

Author Bio

Hi, I'm Carol, the Overseas Marketing Manager at PCBMASTER, where I focus on expanding international markets and researching PCB and PCBA solutions. Since 2020, I've been deeply involved in helping our company collaborate with global clients, addressing their technical and production needs in the PCB and PCBA sectors. Over these years, I've gained extensive experience and developed a deeper understanding of industry trends, challenges, and technological innovations.

Outside of work, I'm passionate about writing and enjoy sharing industry insights, market developments, and practical tips through my blog. I hope my posts can help you better understand the PCB and PCBA industries and maybe even offer some valuable takeaways. Of course, if you have any thoughts or questions, feel free to leave a comment below—I'd love to hear from you and discuss further!