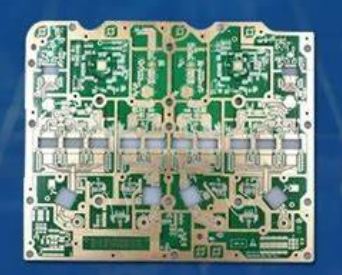

Copper-Aluminum Hybrid PCBs: Unveiling a New Chapter in Electronic Circuits

In the realm of printed circuit boards (PCBs), continuous technological innovation drives the constant evolution of materials and designs. As a standout in this field, copper-aluminum hybrid PCBs are emerging, injecting strong impetus into the performance enhancement and function expansion of electronic devices.

The Blend of Material Properties: A Match Made in Heaven for Complementary Performances

Traditional PCBs predominantly use copper as the sole conductive material. In contrast, copper-aluminum hybrid PCBs ingeniously incorporate aluminum, achieving an overlay of material advantages. Copper boasts excellent electrical conductivity, with minimal electron transmission losses in copper traces, ensuring the stable transmission of high-speed and high-frequency signals. It is thus the ideal choice for handling intricate and sophisticated circuits. Aluminum, on the other hand, is renowned for its outstanding heat dissipation capabilities. With a relatively high thermal conductivity, it can swiftly disperse the heat generated by electronic components, preventing performance degradation or even component damage caused by local overheating. The combination of the two enables the PCB to conduct electricity efficiently while effectively dissipating heat, as if finding a suitable "heat sink" for the "heart" and "blood vessels" of an electronic device.

Challenges and Breakthroughs in the Manufacturing Process

Manufacturing copper-aluminum hybrid PCBs is no easy feat. Due to the differences in the physical and chemical properties of copper and aluminum, achieving a stable bond between the two on the same substrate is a crucial challenge. During the etching process, the etching solution corrodes copper and aluminum at different rates, necessitating precise control of process parameters. Even the slightest deviation can affect the precision of the circuit traces. To address this, researchers have developed a multi-stage etching method, setting up separate etching stages according to the characteristics of copper and aluminum to ensure the accurate formation of circuits. In the lamination process, the treatment of the copper-aluminum bonding surface is of particular importance. Special surface treatment agents are applied to enhance the adhesion between the metals, tightly connecting the copper and aluminum materials in different layers and eliminating defects such as delamination and blistering, thus laying a solid foundation for subsequent processing and long-term use.

Shining in Diverse Application Scenarios

In the field of computer hardware, high-performance CPUs and GPUs consume a large amount of power and generate intense heat during operation. Copper-aluminum hybrid PCBs have thus become the new favorite for motherboards. They not only ensure a stable power supply but also quickly dissipate heat, keeping the chips running at low temperatures. As a result, gamers no longer have to worry about lagging or frequency throttling. The radio frequency modules in communication base stations also benefit. High-frequency signals are transmitted losslessly through copper traces, while the aluminum material promptly dissipates the heat from power amplifier components, ensuring the continuous and stable transmission and reception of signals, safeguarding the stable operation of 5G and even future 6G communication networks. The electronic control units (ECUs) in new energy vehicles also favor copper-aluminum hybrid PCBs. The high-efficiency operation and heat dissipation requirements of complex in-vehicle circuits are effortlessly met by this small circuit board, facilitating the significant progress of vehicle intelligence and electrification.

Industry Outlook: Endless Potential Awaits Exploration

As electronic products continue to evolve towards smaller, more powerful, and smarter designs, copper-aluminum hybrid PCBs hold even broader prospects. In the future, materials scientists plan to further optimize the copper-aluminum ratio and microscopic structure to boost performance. Moreover, with the maturation of manufacturing processes, the production cost is expected to decline. By then, from consumer-grade smart wearables and smart homes to industrial-grade automation production line controls and the precision circuits in aerospace equipment, copper-aluminum hybrid PCBs will serve as the core support, continuously unlocking the infinite possibilities of the electronic world and leading circuit technology to new heights.