FPC Flexible Printed Circuit Board Design Guide 7 Core Principles and 2024 Practical Data Analysis

Author: Jack Wang

I.Why Are Flexible Printed Circuit Boards Reshaping the Electronics Industry?

According to the latest report by Grand View Research, the global flexible printed circuit board (FPC) market size exceeded $16.2 billion in 2024 and is projected to reach $26 billion by 2028, maintaining a compound annual growth rate (CAGR) of 11.5%. From foldable smartphones (Samsung Galaxy Z Fold6's bending life upgraded to 300,000 cycles) to flexible electrodes for brain-computer interfaces, FPCs have become the core carrier for lightweight and highly reliable electronic devices.

II.The Golden Rules of Material Selection

1. Mathematical Relationship Between Substrate Thickness and Flexibility (2024 Experimental Data):

①10μm PI substrate achieves a dynamic bending radius of 2.8mm (meeting IPC-6013 Class 3 standards).

②Ultra-thin PET substrate (20μm) reduces costs by 35%, but exhibits 12% resistance fluctuation after prolonged bending.

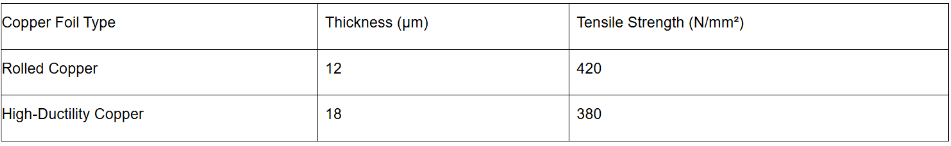

2. Impact of Copper Foil Selection on Reliability:

III. Three Critical Mistakes in Electrical Design

1. Effects of Dynamic Bending on Signal Transmission:

①Differential impedance deviation can reach ±10% under bending (2024 test data).

②Use curved traces in bending areas (curvature radius ≥5× trace width).

2.Optimized High-Frequency Signal Attenuation Formula:

(f: Frequency/GHz, ΔC: Capacitance variation due to bending)

IV.The Survival Code for Mechanical Design

1. 2024 Updated Bending Lifetime Model:

(T: Operating temperature (°C), R: Bending radius, t: Total thickness)

2. Smart Wearable Device Case Study:

①Flexible printed circuit board in a smart ring (0.1mm thickness).

②Passed 200,000 bending cycles (R=1.2mm, temperature range: -20°C to 60°C).

V.The Hidden Battlefield of Manufacturing Processes

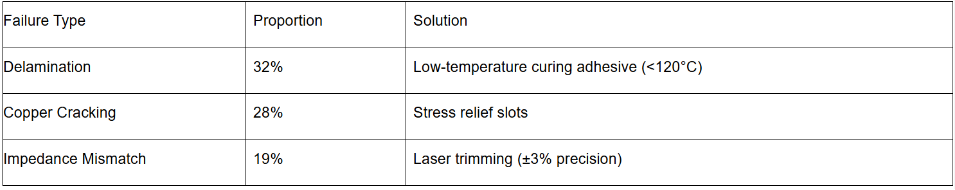

2024 Industry Failure Statistics:

VI.Case Study: Satellite Communication Flexible Printed Circuit Baord Design

1. Extreme Environment Test Data:

①Insulation resistance >10¹²Ω in a vacuum (10⁻⁶ Pa).

②Full functionality under 100 krad radiation dose.

2. Lightweight Design Breakthrough:

Hollow structure reduces weight to 1/6 of traditional PCBs (0.15g/cm²).

VII.Top 5 Technology Trends for the Next 3 Years

1.Self-Healing FPCs (Crack healing rate >90%).

2.Photonic Crystal Flexible Circuits (Transmission loss <0.1dB/cm).

3.Stretchable Conductive Materials (Elongation rate >200%).

2024 Design Checklist

1.Is grid copper used in dynamic bending areas (40%~60% open area ratio)?

2.Are ±10% impedance margins reserved for critical signal traces?

3.Is the cover film opening edge ≥0.3mm from traces?

4.Are stress-relief structures designed at flexible printed circuit board mounting areas?

Data Sources:

1.IPC-6013E Flexible Circuit Verification Standard (2024 Revision)

2.JPCA Global FPC Industry Report (2024 Q1)

3.Tesla Humanoid Robot Flexible Joint Whitepaper

4.Huawei NearLink Communication Protocol Specifications

Author: Jack Wang