Breakthrough in Miniaturized PCBA Manufacturing Defense Strategy Against Solder Bridging in PCB Assembly Processes

Author: Jack Wang

I. The Critical 0.1mm Battlefield

In the era of 5G smart hardware, PCB assembly density is increasing at an annual rate of 18%. As 0201 components become standard in PCBA manufacturing, solder bridging defects have evolved into a critical technical bottleneck. Key findings reveal:

1. PCB assembly layouts with over 5 solder joints per cm² face a 3.2x higher bridging risk.

2. PCBA products using 0.4mm-pitch BGA packages incur 70% higher rework costs.

3. 35% of early failures in miniaturized PCBA modules for wearables stem from hidden solder bridging.

(Diagram: Evolution of solder joint density in mainstream electronic products)

II. Full-Process Risk Analysis in PCB Assembly

1. Triple Traps in Design

① Component Layout Imbalance: A TWS earphone PCBA case study showed 85% of components concentrated on one side, causing reflow soldering offset.

② Pad Spacing Crisis: Bridging rates surge by 400% when 0402 component spacing falls below 0.25mm.

③ Solder Mask Defects: Failure to adopt micro-pitch SMD pads increases PCBA defect rates by 52%.

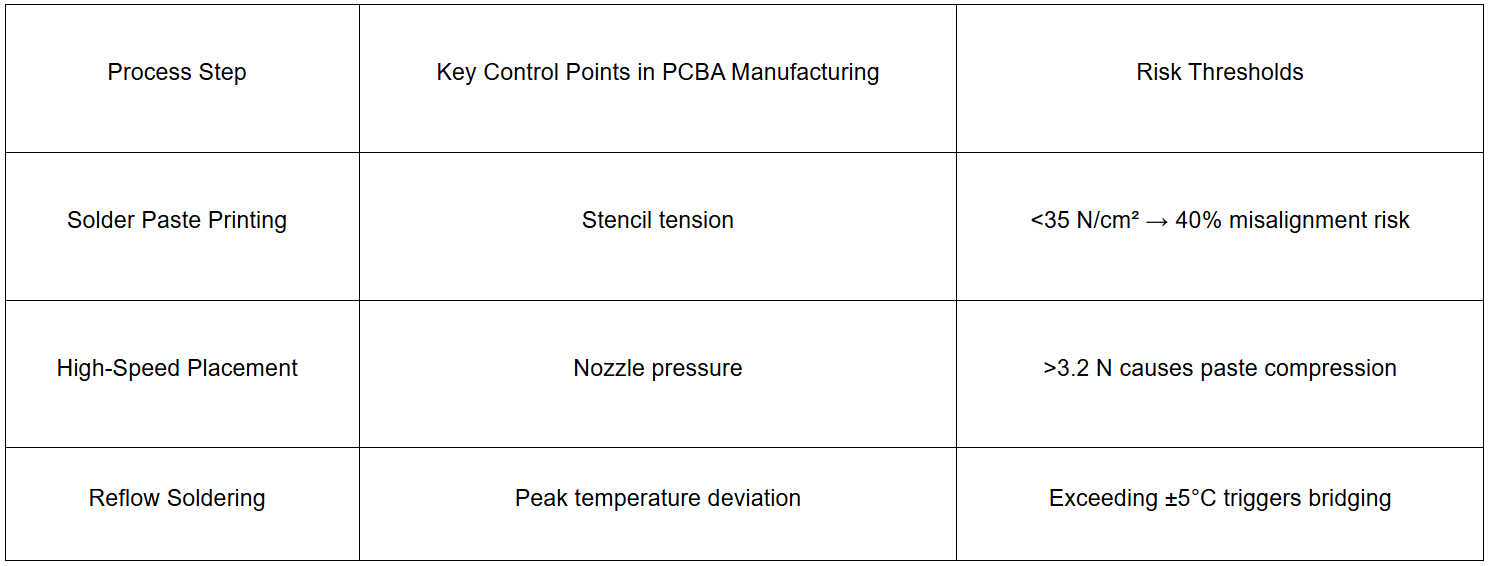

2. Invisible Killers in Manufacturing

3. Deadly Material Combinations

① Uncontrolled Paste Fluidity: PCB assembly-specific solder paste with viscosity <70 Pa·s reduces bridging by 65%.

② Stencil Deformation: Nano-coated stencils improve PCBA paste deposition accuracy to ±8μm.

③ Flux Residue: Low-residue formulations suppress hidden bridging risks below 0.3%.

III. Golden Protection System for PCBA Manufacturing

1. Intelligent DFM Design Matrix

① Establish PCB assembly component thermodynamics models (0.01mm² precision).

② Define spacing standards: 0402 ≥0.3mm, 0201 ≥0.2mm.

③ Implement stepped solder mask design (core area bridge width ≥0.08mm).

2. Process Control Triad

① Paste Printing Monitoring: 3D SPI systems detect thickness deviations (±10μm).

② Placement Pressure Control: Piezoelectric sensors enable 0.01N precision.

③ Dynamic Reflow Profiles: AI temperature control compensates for board warpage.

3. Material Innovations

① Nano-scale solder powder (D50=15μm).

② Self-aligning solder paste (28% optimized surface tension).

③ Low-temperature eutectic alloys (34°C lower melting point).

IV. Advanced Roadmap for PCB Assembly

1. Current Optimal Solutions

① Laser-assisted solder paste printing (<0.01% bridging rate).

② Hybrid selective wave soldering & hot air leveling.

③ X-Ray + AOI dual-mode inspection (detects 15μm defects).

2. Future Technology Roadmap

① Molecular-level solder resist coatings (contact angle >110°).

② Magnetically controlled self-assembly placement.

③ Digital twin-based PCBA virtual manufacturing systems.

V. Value Multipliers in PCBA Manufacturing

Implementing full-process control delivers:

1.First-pass yield >99.95%

2.PCBA rework costs reduced by 92%

3.Product lifecycle extended 3-5x

In the irreversible wave of miniaturization, companies mastering precision PCB assembly control are redefining PCBA manufacturing value chains. Partnering with nano-scale process experts will be decisive in the era of microelectronics.

(Data sources: IPC-7095D standard, ASM PT200 process white paper, Indium Corporation 2024 Solder Technology Annual Report)