A Comprehensive Analysis of PCB Materials Suitable for LED Manufacturing

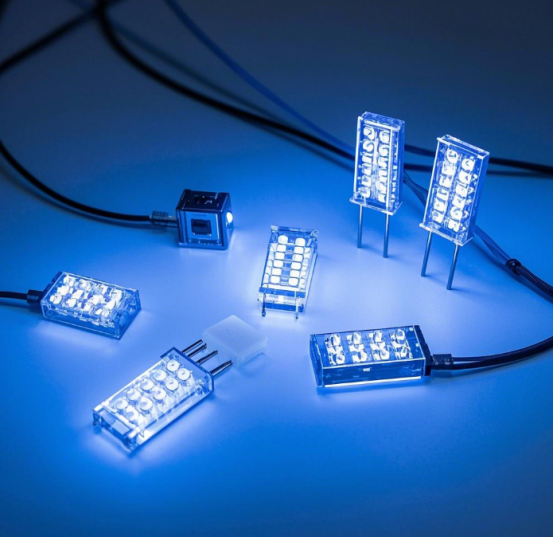

In the era of booming LED lighting and display technologies, printed circuit boards (PCBs), as the crucial components that carry and connect LED elements, have their performance, lifespan, and cost directly related to the materials used. A variety of PCB materials with different characteristics have emerged, each shining brightly in the field of LED applications.

Rigid PCB Materials

FR-4 Boards: The Common Choice

FR-4 boards are a familiar face in the PCB field, composed of epoxy resin and fiberglass cloth. It is widely favored because of its excellent mechanical strength. Even when subjected to a certain degree of external pressure or impact, it can still maintain the integrity of the circuit board and keep the circuits unobstructed. In terms of heat resistance, it can adapt to the normal operating temperature range, laying a solid foundation for the stable operation of LEDs. Its electrical insulation performance is outstanding, eliminating the risks of electric leakage and short circuits, ensuring the smooth running of the circuits. The mature manufacturing process makes FR-4 boards cost-effective, showing great advantages in large-scale production. However, it also has shortcomings. Its heat dissipation ability is poor, and it is difficult to disperse the high heat generated by high-power LEDs during long-term operation in time. So, it is a bit out of place in high-power lighting scenarios. For low-power lighting fixtures such as ordinary indoor LED ceiling lights and simple chandeliers, FR-4 boards are an economical and practical choice.

Aluminum Substrates: Heat Dissipation Pioneers

The structure of aluminum substrates is unique, with copper foil, an insulating layer, and an aluminum sheet stacked on top of each other. The high thermal conductivity of aluminum endows it with extraordinary heat dissipation capabilities. It's like installing a dedicated heat sink for overheating high-power LEDs, allowing heat to be quickly conducted away through the aluminum layer, preventing the lamps from suffering from severe light decay and shortened lifespan due to overheating. In terms of mechanical strength, aluminum substrates can also withstand the impacts of daily installation and transportation. However, the additional aluminum material drives up the cost, and its insulation performance is slightly inferior to that of traditional FR-4. For LED street lights, industrial floodlights, and other lighting fixtures that require long-term high-brightness illumination, aluminum substrates are the top choice. With them, these lights can stand firm and stable even under strong outdoor illumination.

Ceramic Substrates: Performance Kings

Ceramic substrates, with ceramic as the base material, are born with high-end attributes. Their thermal conductivity stands out among all materials, efficiently dissipating the heat generated by LED chips and greatly extending the lifespan of LEDs. At the same time, excellent insulation combined with chemical stability enables them to remain stable whether in humid environments, under acid-base corrosion, or exposed to high temperatures. However, the high cost and brittle nature limit their large-scale popularization. Currently, they are mostly used in the high-power core areas of industrial lighting, as well as in lighting scenarios for aerospace and medical devices where extremely high reliability is required.

Flexible PCB Materials

Polyimide Flexible Printed Circuits (FPC): Agile Dancers

FPCs with polyimide film as the base material are like agile dancers. They have a high wiring density, allowing for delicate circuit layouts in tiny spaces; they are lightweight and thin, hardly adding any extra burden to the product; and, most impressively, their bendable property enables them to easily conform to various complex shapes, opening up creative possibilities for designers. Their electrical insulation and performance are both satisfactory, but their heat resistance is limited. When exposed to high-temperature working conditions, they will show weaknesses. Coupled with their relatively high cost, they are often used in decorative lighting products such as LED light strips that pursue variable shapes and can be bent at will.

Polyester Flexible Printed Circuits: Affordable Alternatives

Polyester flexible printed circuits have entered the public eye because of their relatively low cost. Although they have some capabilities in terms of flexibility and electrical performance, compared with FPCs, their heat resistance, chemical resistance, and mechanical strength are rather insufficient. In some small, entry-level bendable LED devices or mid-to-low-end lighting products with strict cost control, they have gained a foothold with their cost-effectiveness.

Other Special Materials

CEM-1 and CEM-3: Cost-Effective Options

CEM-1 and CEM-3 ingeniously combine paperboard and fiberglass. They are even less expensive than FR-4 and also have basic insulation and mechanical protection capabilities. However, their performance is rather mediocre, and their dimensional stability is relatively poor. They are quietly working in the field of low-end lighting fixtures, providing simple and practical solutions for cost-sensitive projects.

PTFE Boards: High-Frequency Specialists

PTFE boards are known for their low dielectric loss, high temperature resistance, and chemical stability, which makes them stand out in the scenarios of high-frequency and high-speed transmission LED display screens. However, their relatively weak mechanical strength and high cost limit them to only being used in niche areas such as indicator lights for high-end communication devices and high-precision lighting fixtures where extremely high electrical performance is required.

Different LED application scenarios have given rise to a variety of PCB materials. Accurately matching materials with application requirements is the key to creating high-quality, durable, and cost-effective LED products.