What Are Metal Substrates & High - Conductivity Copper Substrates? How Much Do You Know? Ask PCB MASTER COMPANY for an Explanation

I.Basic Information Introduction of Metal Substrate and High Conductivity Copper Substrate

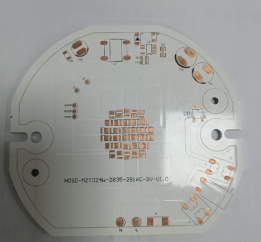

1.Material Overview

The high - conductivity copper substrate is a kind of metal substrate material laminated by high - performance copper foil and an insulating dielectric layer. It has excellent thermal conductivity, electrical performance and good processing performance, and is an important part of the heat dissipation solutions for electronic components. The high - conductivity copper substrate is widely used in the thermal management systems of high - frequency and high - power electronic equipment, and can effectively improve the stability and reliability of the equipment. For technical or analytical applications, having detailed product information is essential to ensure the substrate meets specific requirements.

2.Type Classification

The high - conductivity copper substrate can be divided into multiple types according to its structure, performance and application fields. Common classification methods include:

Classification by structure: single - layer high - conductivity copper substrate, double - layer high - conductivity copper substrate, multi - layer high - conductivity copper substrate.

Classification by copper foil thickness: thin - type high - conductivity copper substrate (such as 35μm copper foil), standard - type high - conductivity copper substrate (such as 70μm - 140μm copper foil), thick - type high - conductivity copper substrate (such as 280μm copper foil).

Classification by thermal conductivity: ordinary - thermal - conductivity high - conductivity copper substrate, high - thermal - conductivity high - conductivity copper substrate.

3.Core Technologies

The core technologies of high - conductivity copper substrates mainly include:

Copper Foil Preparation Technology: As the main heat - conducting material of high - conductivity copper substrates, the preparation technology of copper foil directly affects the thermal conductivity of the substrates. Common copper foil preparation technologies include electroplating and chemical vapor deposition.

Dielectric Layer Preparation Technology: The dielectric layer is an important part of high - conductivity copper substrates, and its preparation technology is related to the electrical performance and thermal stability of the substrates. Common dielectric layer preparation technologies include resin coating and hot - pressing.

Lamination Technology: Lamination technology is a crucial step in the production of high - conductivity copper substrates and directly affects the overall performance of the substrates. High - quality lamination technology can ensure a close bond between the copper foil and the dielectric layer and improve the thermal and electrical performance of the substrates.

Certain copper substrates and coatings are specifically developed for particular performance or application requirements, ensuring optimal results for targeted uses. In the order of manufacturing steps, preparation, lamination, and quality checks are performed to ensure optimal substrate performance. It is also important to determine the appropriate technology and process based on the intended application and required properties.

4.Thermal Conductivity

High - conductivity copper - substrate circuit boards have excellent thermal conductivity, and their thermal conductivity coefficients are much higher than those of traditional metal and plastic materials. Depending on the thickness of the copper foil and the material of the dielectric layer, the thermal conductivity of high - conductivity copper substrates may also vary. In actual applications, an appropriate high - conductivity copper substrate can be chosen according to specific requirements to meet the equipment’s heat - dissipation performance requirements. It is important to determine the appropriate copper substrate by assessing the application's thermal and electrical needs, ensuring the selected substrate matches the performance criteria.

5.Copper Foil Requirements

As the main heat - conducting material of high - conductivity copper substrates, the performance of copper foil directly affects the thermal conductivity of the substrates. The main requirements for copper foil used in high - conductivity copper substrates are as follows:

Thickness Requirement: The thickness of the copper foil can be selected according to actual needs. Common copper foil thicknesses include 35μm, 70μm, 105μm, 140μm, and 280μm.

Conductivity: The copper foil should have good conductivity to ensure the stable operation of high - conductivity copper substrates in high - frequency and high - power equipment.

Surface Quality: The copper foil surface should be flat, without scratches, oxidation, and other defects to improve the bonding strength between the copper foil and the dielectric layer. It is necessary to check the copper foil for defects or quality issues before use to ensure optimal performance.

6.Application Areas

High - conductivity copper substrates are widely used in the following areas:

Communication Field: Such as the heat - dissipation systems of base stations, switches, and routers.

Power Supply Field: Such as the heat - dissipation systems of UPS power supplies and electric vehicle charging piles.

Industrial Control Field: Such as the heat - dissipation systems of PLC controllers and inverters.

Military Field: Such as the heat - dissipation systems of radars and missiles.

7. Mechanical Properties

High - conductivity copper substrates have good mechanical properties, including bending strength, tensile strength, hardness, and other indicators. These mechanical properties ensure that high - conductivity copper substrates are not easily deformed, cracked, or damaged during processing and use, improving the reliability and durability of the substrates. At the same time, good mechanical properties also facilitate secondary processing operations such as cutting and drilling of high - conductivity copper substrates to meet different application requirements.

II.Introduction to PCB Services

In the world of Printed Circuit Boards (PCBs), the choice of substrate is a fundamental factor that shapes the quality, performance, and longevity of electronic products. The substrate serves as the base material upon which circuits are constructed, and its characteristics—such as thermal conductivity, stability, and durability—play a crucial role in determining the overall effectiveness of the PCB. For example, aluminum substrate is widely recognized for its enhanced heat dissipation and stable mechanical properties, making it a commonly selected material in demanding applications. Selecting the most suitable substrate is not only important for the immediate performance of the product but also for its long-term reliability and life span. As PCB services continue to evolve around the world, understanding the differences between substrate materials and their impact on the final product is essential for manufacturers and designers aiming to deliver high-quality, stable, and efficient electronic solutions.

III.Substrate Options

When choosing a substrate for PCB manufacturing, there is a wide variety of materials and substrate types to consider, each offering unique features and benefits for different applications. Metal substrates, such as aluminum and copper, are especially valued for their durable structure and superior heat dissipation, making them suitable for high-power and high-reliability environments. The thickness of the substrate is another important factor; for example, a greater thickness can provide enhanced mechanical strength and stability, which is ideal for industrial or automotive applications. Conversely, thinner substrates are often chosen for compact devices where space and weight are at a premium. Surface coatings and treatments further enhance the substrate by providing protection against moisture, corrosion, and other environmental factors, thereby extending the life and durability of the PCB. By carefully evaluating the type, condition, and features of available substrates, manufacturers can select the most suitable option for each specific application.

IV.Surface Preparation and Treatment

Proper surface preparation and treatment are essential steps in ensuring the quality and performance of PCBs. The technique used to prepare the substrate surface—whether it involves cleaning, etching, or applying a primer—directly affects the adhesion of coatings and the reliability of component mounting. For aluminum substrates, specialized methods may be required to achieve optimal bonding and protection. The choice of preparation method depends on the substrate type, the intended application, and the desired level of protection. Equipment and techniques must be selected to match the specific requirements, balancing factors such as cost, preparation time, and the complexity of the process. By determining the most suitable approach for each project, manufacturers can ensure that the substrate surface is properly prepared, leading to improved performance and longer-lasting PCBs.

V.Materials and Manufacturing

The selection of materials and the manufacturing process are critical to producing high-quality PCBs that meet the demands of modern electronic applications. Metal substrates like aluminum and copper are widely used due to their excellent thermal and electrical properties, which are essential for efficient heat management and signal integrity. The manufacturing process typically involves several stages, including cutting the substrate to size, drilling holes for components, and applying protective coatings. The choice of material, such as a high-grade aluminum substrate, can significantly enhance the thermal performance and reliability of the final product. Additionally, the details of the manufacturing process—including the equipment and techniques employed—can influence the consistency, cost, and overall quality of the PCB. By carefully selecting materials and optimizing manufacturing methods, producers can deliver products that are both cost-effective and high-performing.

VI.Design and Assembly

The design and assembly phases of PCB production are closely linked to the properties of the chosen substrate. The type and condition of the substrate influence key design decisions, such as component placement, trace routing, and board layout. During assembly, different materials may require specific methods and equipment to ensure secure and durable connections. For example, working with aluminum substrates often involves specialized soldering techniques and handling procedures to maintain the integrity of the board. The size and complexity of the substrate can also impact assembly, with larger or more intricate boards necessitating additional support and careful management. By thoughtfully choosing the right substrate and adapting the design and assembly process accordingly, manufacturers can achieve reliable, high-quality PCBs that meet the precise needs of their applications.

Why PCBMASTER:https://www.pcbmaster.com/why

Join US:https://www.pcbmaster.com/register