3D Printed Electronics When Will It Replace Traditional PCBA Processes

In the field of electronic product manufacturing, the traditional PCBA (Printed Circuit Board Assembly) process has dominated for decades. Its core processes include substrate etching, component placement, reflow soldering, and other links. However, with the breakthrough progress of 3D printed electronics technology, the industry has begun to consider a key question: Can this disruptive technology completely replace PCBA? And when can this happen?

This article will conduct an in - depth analysis from three dimensions: technological maturity, economic feasibility, and application scenarios. Based on the latest research data from MIT and IDTechEx, it will predict the time window for technological substitution.

I. Technological Status: Breakthroughs and Limitations of 3D Printed Electronics

1. Core Progress

①Multi - material Integrated Printing: Nano Dimension's DragonFly IV can simultaneously print conductive silver paste (with a resistivity of 2.5 μΩ·cm) and insulating polymers, achieving a 10 - layer interconnected structure.

②Embedded Components: Optomec's Aerosol Jet technology can directly print 0201 - sized resistors/capacitors on curved substrates with an accuracy of ±25 μm.

③Breakthroughs in Flexible Electronics: The UK's National Flexible Electronics Center (CPI) has developed 3D - printed circuits that can be stretched by 200%, which are used in wearable medical sensors.

2. Key Bottlenecks

①Conductive Material Performance: The cost of silver paste is 15 times that of copper foil, and high - frequency losses (insertion loss > 3 dB/cm at 10 GHz) limit its application in radio - frequency fields.

②Resolution Limitations: The current minimum line width is 50 μm (while traditional etching can reach 10 μm), and it cannot support BGAs with a pitch below 0.3 mm.

③Reliability Defects: The shear strength of 3D - printed solder joints is only 12 MPa (compared to 35 MPa for traditional SMT), and the number of failure cycles in thermal cycling tests (-40°C - 125°C) is less than 200 times.

II. Economic Showdown: The Disruption and Reconstruction of the Cost Model

1. Advantages in Small - batch Production

①Traditional PCBA: It is necessary to pay for mold costs (stencil/$500), pick - and - place machine change - over costs ($500), and pick - and - place machine change - over costs ($200/time). The single - board cost for a quantity of 1,000 is $8.5.

②3D Printed Electronics: There are no fixed costs, and the single - board cost for a quantity of 1,000 is $6.2 (Data source: Jabil 2023 White Paper).

2. Economic Deficit in Mass Production

Quantity | Traditional PCBA Cost | 3D Printed Electronics Cost |

1,000 | $8.5 | $6.2 (-27%) |

10,000 | $3.1 | $5.8 (+87%) |

100,000 | $1.7 | $4.3 (+153%) |

Note: Costs include materials, equipment depreciation, and labor.

III. Substitution Path: Time Schedule for Breakthroughs in Different Scenarios

1. 2025 - 2028: Dominance of Flexible/Irregular Electronics

①Medical Field: 3D - printed ingestible sensors (such as the Proteus Digital Health project) will fully replace traditional flexible printed circuits (FPCs).

②Automotive Field: In - situ printing will be used for the curved center console circuits (such as in the BMW iNEXT), reducing connectors by 60%.

2. 2030 - 2035: Rise of the Hybrid Manufacturing Paradigm

①Military and Aerospace: Lockheed Martin has printed 3D antennas on satellite brackets, reducing the assembly process by 75%.

②Consumer Electronics: Printed circuits will be integrated into the internal support structures of mobile phones (such as in Apple's patent US20230132528), saving 30% of space.

3. After 2040: Critical Point for Full - process Substitution

Three key technologies need to be broken through:

①Nano - copper Printing: Solve the problems of high - frequency loss and cost (Fraunhofer Institute predicts its commercialization in 2038).

②Sub - micron Precision: Achieve a 10 - μm line width (requiring the maturity of electron - beam direct - writing technology).

③Self - repairing Materials: Cope with bending and cracking (MIT's self - repairing polymers have passed 50,000 bending tests).

IV. Enterprise Action Guide: Crossing the Technology Chasm

1. Short - term Strategies (2024 - 2027)

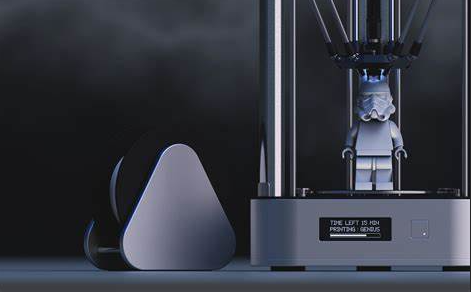

①Hybrid Production Lines: Deploy 3D printing units beside traditional SMT lines for rapid prototyping.

②Talent Reserves: Train "additive - thinking" engineers who master skills such as topological optimization and multi - physical - field simulation.

2. Long - term Investments (2028 - 2035)

①Material Alliances: Collaborate with Henkel and Heraeus to develop low - cost conductive polymers.

②Standard Setting: Take the lead in formulating IPC - 3DP printed electronics reliability standards (such as the revision of IPC - 2291).

Conclusion: Not "Replacement" but "Reconstruction"

3D printed electronics will not completely replace traditional PCBA. Instead, it will give rise to a hierarchical manufacturing ecosystem:

Ultra - large - scale production (>1 million): Traditional PCBA will still dominate.

Small - and medium - batch customization: 3D printing has obvious economic advantages.

Extreme application scenarios (high - temperature/flexible): 3D printing becomes the only option.

According to Gartner's prediction, by 2030, 30% of electronic assembly processes will be transformed by additive technologies. Enterprises need to abandon the "either - or" mindset and shift to a hybrid manufacturing strategy to gain the upper hand in the technological revolution.

Author: Jack Wang