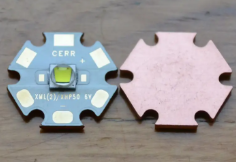

Metal base material ------ High conductivity copper base technology

1. Material Overview

The high-conductivity copper substrate is a kind of metal substrate material laminated by high-performance copper foil and an insulating medium. It has excellent thermal conductivity, electrical properties and good processing performance, and is an important part of the heat dissipation solutions for electronic components. The high-conductivity copper substrate is widely used in the thermal management systems of high-frequency and high-power electronic equipment, and can effectively improve the stability and reliability of the equipment.

2. Material Overview

The high-conductivity copper substrate is a kind of metal substrate material laminated by high-performance copper foil and an insulating medium. It has excellent thermal conductivity, electrical properties and good processing performance, and is an important part of the heat dissipation solutions for electronic components. The high-conductivity copper substrate is widely used in the thermal management systems of high-frequency and high-power electronic equipment, and can effectively improve the stability and reliability of the equipment.

3.Core Technologies

The core technologies of high-conductivity copper substrates mainly include:

Copper Foil Preparation Technology: As the main heat-conducting material of high-conductivity copper substrates, the preparation technology of copper foil directly affects the thermal conductivity of the substrates. Common copper foil preparation technologies include electroplating method, chemical vapor deposition method and so on.

Dielectric Layer Preparation Technology: The dielectric layer is an important part of high-conductivity copper substrates, and its preparation technology is related to the electrical properties and thermal stability of the substrates. Common dielectric layer preparation technologies include resin coating method, hot pressing method and so on.

Lamination Technology: Lamination technology is a crucial step in the production of high-conductivity copper substrates and directly affects the overall performance of the substrates. High-quality lamination technology can ensure a tight bond between the copper foil and the dielectric layer, improving the thermal conductivity and electrical properties of the substrates.

4.Thermal Conductivity

The high-conductivity copper substrates for circuit boards possess excellent thermal conductivity, and their thermal conductivity coefficients are much higher than those of traditional metal materials and plastic materials. Depending on the thickness of the copper foil and the materials of the dielectric layer, the thermal conductivity of high-conductivity copper substrates may also vary. In practical applications, appropriate high-conductivity copper substrates can be selected according to specific requirements to meet the heat dissipation performance requirements of the equipment.

5.Thermal Conductivity

The high-conductivity copper substrates for circuit boards possess excellent thermal conductivity, and their thermal conductivity coefficients are much higher than those of traditional metal materials and plastic materials. Depending on the thickness of the copper foil and the materials of the dielectric layer, the thermal conductivity of high-conductivity copper substrates may also vary. In practical applications, appropriate high-conductivity copper substrates can be selected according to specific requirements to meet the heat dissipation performance requirements of the equipment.

6.Application Fields

High-conductivity copper substrates are widely used in the following fields:

Communication Field: For example, in the heat dissipation systems of equipment such as base stations, switches, and routers.

Power Supply Field: For example, in the heat dissipation systems of equipment such as UPS power supplies and electric vehicle charging piles.

Industrial Control Field: For example, in the heat dissipation systems of equipment such as PLC controllers and frequency converters.

Military Field: For example, in the heat dissipation systems of equipment such as radars and missiles.

7.Mechanical Properties

High-conductivity copper substrates possess good mechanical properties, including indexes such as flexural strength, tensile strength and hardness. These mechanical properties ensure that high-conductivity copper substrates are not prone to deformation, cracking or damage during the processing and usage processes, improving the reliability and durability of the substrates. Meanwhile, the good mechanical properties also facilitate secondary processing operations such as cutting and drilling on high-conductivity copper substrates to meet different application requirements.