IC Bonding Essential Techniques for Modern Semiconductor Applications

Introduction to Bonding Techniques

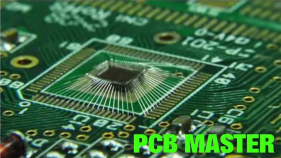

·Wire bonding is a crucial technique in the semiconductor industry for creating reliable connections between integrated circuits and packaging substrates.

·The wire bonding process involves using fine wire materials, such as gold, aluminum, or copper. These types of wire are selected based on their compatibility with different bonding techniques and specific application requirements.

·Wire bonding techniques, including ball bonding and wedge bonding, are used to connect bonding wires to bond pads securely.

·There are various wire bonding options available, offering a range of techniques and materials to suit different reliability, performance, and customization needs in semiconductor manufacturing and PCB assembly.

·The choice of wire bonding technique depends on the application type, IC packaging technology, and material compatibility.

·Wire bonding serves as a flexible interconnect technology, making it a cost-effective and adaptable solution for a wide variety of electronic applications.

Bonding Materials and Processes

·Gold wire bonding is a popular choice due to its excellent electrical conductivity and reliability. Gold (Au), especially pure gold wire, offers superior ductility and compatibility with silicon chips, making it ideal for high-reliability applications.

·Aluminum wire and copper wire (aluminum Al, copper Cu) are also used, with copper wire offering higher electrical conductivity and lower cost. Silver (Ag) and silver wire are alternative materials, valued for their good electrical and thermal conductivity and corrosion resistance. The selection of wire material also depends on wire diameter, with wire diameters and thin wire (up to 75 μm) being important for high-speed, high-frequency, or fine pitch applications. Proper wire diameter selection is crucial for performance, reliability, and cost-effectiveness.

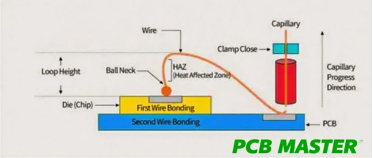

·The wire bonding process involves optimizing bonding parameters, such as bonding force, ultrasonic energy, temperature, and process methods like thermocompression bonding. During thermocompression bonding, thermal energy and heat softens the metals, facilitating bond formation and reliable metal-to-metal connections. Careful control of these parameters ensures robust and consistent wire bonds.

·Wire bonding materials, including gold, aluminum, and copper, require specific bonding parameters and process control.

·A precise manufacturing process and the adoption of cost effective wire bonding solutions are essential for ensuring reliable interconnections and reducing manufacturing expenses in semiconductor device production.

Bond Pad and Wire Bond

·The bond pad is a critical component in the wire bonding process, requiring careful design and preparation. The terms bonding pad and bonding pads are often used to describe the target surfaces on the semiconductor device where the wire is attached, and proper preparation of these bonding pads is essential for strong, reliable connections.

·The wire bond is formed by creating a strong metallurgical bond between the bond wire and the bond pad. Specific techniques such as wedge bonds, wedge bond, and wedge bonded are used, especially with materials like copper and aluminum, to ensure optimal electrical and mechanical performance.

·Bond pad metallization and barrier layers influence bond quality, with common failure modes including ball bonds fracture and pad liftoff.

·The wire bonding process involves precise control of bonding parameters to ensure reliable wire bonds.

·The package substrate plays a crucial role in supporting the bond pad and contributes significantly to the overall reliability of the bond.

Bonding Wires and Applications

·Fine wire materials, such as gold, aluminum, and copper, are used in wire bonding applications for a variety of electronic components, including integrated circuits, power devices, semiconductor packaging, semiconductor devices, and semiconductor chips.

·The choice of wire material depends on the application, environment, and required electrical and mechanical properties. Wire bonding plays a critical role in signal transmission, power distribution, and overall electrical performance by establishing reliable connections between the chip, its external leads, and the rest of the circuitry. Optimized wire bonding processes and materials contribute to improved electrical performance in high-density and miniaturized assemblies.

·Wire bonding is used in a wide range of applications, including integrated circuits, power devices, semiconductor packaging, and connecting external leads to ensure robust electrical connectivity. The process is essential for maintaining signal integrity and device reliability.

·The wire bonding industry is shifting towards finer pitch bonding, fine pitch, and alternative wire materials, such as copper and coated copper wire, to address the demands of thermal management, high volume production, and miniaturization. Fine pitch bonding is especially important for advanced applications requiring very small interconnect pitches, such as in modern IC packaging. Quality control is maintained through rigorous testing methods, including pull tests and shear tests, to ensure bond integrity. Modern manufacturing relies on advanced wire bonding machines and wire bonding machine technology, which offer ultra-precise control and automation for high yield and reliability. The industry also faces wire bonding challenges, such as wire sagging and loop formation, which are addressed through process optimization, advanced equipment, and comprehensive testing.

Environmental and Safety Considerations in IC Bonding

·As the wire bonding industry continues to advance, environmental and safety considerations have become increasingly important in the wire bonding process. The fabrication of integrated circuits relies on precise bonding processes to create reliable electrical connections, but these processes can have significant environmental impacts if not managed responsibly. The use of materials such as gold, copper, and aluminum in wire bonding generates waste and requires careful resource management to minimize environmental footprints. Additionally, the wire bonding process often involves the use of chemicals and high temperatures, which must be controlled to prevent emissions and ensure workplace safety.

·Safety is a critical concern in the wire bonding industry, especially when handling fine wires and operating wire bonding equipment that utilizes ultrasonic energy and heat. Proper training, protective equipment, and process controls are essential to safeguard workers from potential hazards such as burns, electrical shocks, and exposure to hazardous substances. The industry also adheres to strict regulations and standards to ensure that the bonding process does not compromise the health of employees or the environment.

·To address these challenges, manufacturers are adopting more sustainable practices, such as recycling excess wire materials, optimizing bonding parameters to reduce energy consumption, and implementing closed-loop systems for chemical management. These efforts not only help reduce the environmental impact of the wire bonding process but also contribute to the overall reliability and performance of semiconductor devices. As the demand for advanced integrated circuits grows, the wire bonding industry remains committed to continuous improvement in environmental stewardship and workplace safety, ensuring that the bonding process supports both technological innovation and responsible manufacturing.

Challenges and Quality Control

·Wire bond failures, such as peeling or breaking, remain a major reliability issue in wire bonding. These reliability issues are often linked to wire bonding challenges, including wire sagging, wire sweep, and loop formation.

·Quality control measures, including destructive bond pull tests and visual inspections, are used to verify bond strength and reliability. Various testing methods, such as pull tests, shear tests, and imaging techniques, play a crucial role in ensuring bond integrity and are often performed according to industry standards.

·The wire bonding process requires precise control of bonding parameters, especially bonding force and bond formation, to minimize defects and ensure reliable wire bonds.

·Ultrasonic energy and thermosonic bonding are used to improve bond quality and reduce wire bond failures.

Bond Strength and Reliability

·Bond strength is critical for the reliability of wire-bonded semiconductor devices, with bonding force and proper bond formation being key factors in achieving strong, durable connections.

·The wire bonding process involves optimizing bonding parameters, including bonding force, to achieve desired electrical and mechanical properties and ensure high-quality bond formation.

·Wire bond reliability is affected by environmental factors, such as temperature, humidity, and thermal cycling, which can lead to reliability issues.

·The choice of wire material and bonding technique, as well as considerations for thermal management, influences bond strength and reliability.

Applications of IC Bonding

·Wire bonding is widely used in the semiconductor industry for establishing electrical connections in integrated circuits and packaging, including connections between the semiconductor chip and the package substrate.

·The technique is used in a range of applications, including power devices, semiconductor packaging, high-performance computing, and as a key process for bonding chips to the package substrate to ensure device reliability.

·IC bonding enables the transfer of electrical signals and power within semiconductor devices, supporting integrated circuit functionality by creating reliable connections between the chip and its external leads.

·The wire bonding industry is driven by the demand for smaller, faster, and more reliable semiconductor devices.

Future Trends and Advancements

·The wire bonding industry is evolving to meet the demands of smaller architectures and complex chip designs.

·Advances in wire bonding technology, including fine pitch bonding and alternative wire materials, are supporting higher performance and reliability. High volume production is also driving technological advancements to meet industry needs.

·The use of ultrasonic and thermosonic bonding is becoming more prevalent, offering improved bond quality and reduced wire bond failures.

·The development of new wire bonding materials and techniques, such as silver and palladium-coated copper wire, is expected to drive future growth in the industry, with a focus on improved electrical performance.

FAQs

A. What is the difference between wire bonding and flip-chip bonding?

Q. Wire bonding has lower costs, relatively cheaper equipment, and strong material compatibility. However, the bonding wires introduce higher parasitic inductance, making it unsuitable for high-frequency applications, and the bonding density is limited. Flip-chip bonding can achieve higher connection density and lower signal delay, making it suitable for high-frequency and high-speed applications, but the equipment and process costs are higher.

A. How to ensure the reliability of IC bonding?

Q. Reliability can be ensured by selecting substrate materials with a coefficient of thermal expansion matching the chip, optimizing bonding process parameters (such as controlling temperature, pressure, etc.), and performing strict quality inspections (such as AOI inspection, X-Ray inspection, etc.). Additionally, using processes like underfill to alleviate thermal stress also helps improve reliability.

A. What is the approximate production cycle for different IC bonding processes?

Q. The production cycle for wire bonding is shorter, with single-chip processing time taking only 1 - 2 seconds. For batch production, the process from programming to shipment can generally be completed in 3 - 5 days. The production cycle for flip-chip bonding is longer, typically requiring 3 - 5 days. Hybrid bonding has the longest production cycle; the production flow for a single batch of 10,000 chips may require 7 - 10 days.

Why PCBMASTER: https://www.pcbmaster.com/why

Join US:https://www.pcbmaster.com/login