Application Products of Aluminum Oxide Ceramic-Based PCBs Core Technology Breakthroughs from High-Power LEDs to New Energy Vehicles

Author: Jack Wang

Ⅰ. The Technical Foundation of Aluminum Oxide Ceramic PCBs

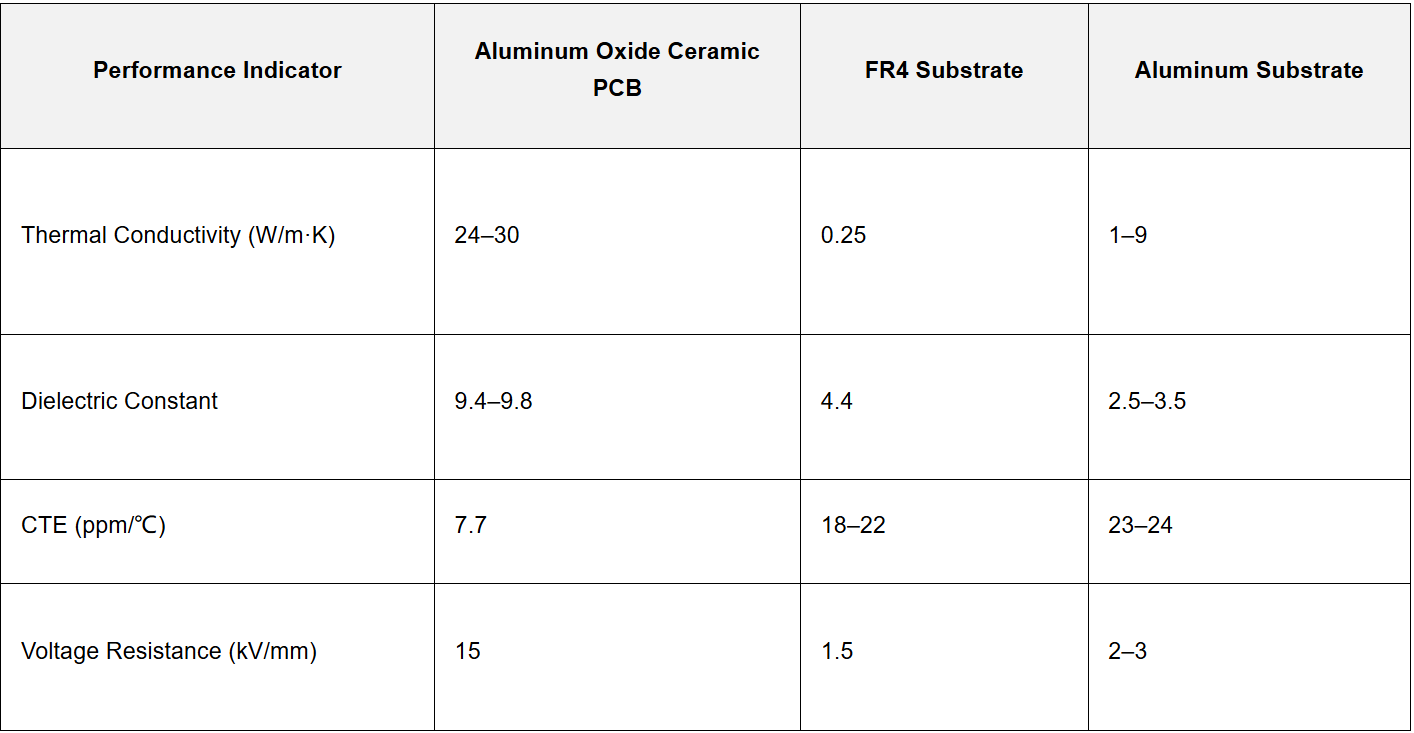

Aluminum oxide ceramic-based PCBs use 96% or 99% pure aluminum oxide (Al₂O₃) as the substrate, combined with copper layers through processes like DBC (Direct Bonded Copper), AMB (Active Metal Brazing), or DPC (Direct Plating Copper). Their core advantages include:

· Thermal Conductivity: 24–30 W/m·K, over 100 times higher than traditional FR4 substrates, enabling rapid heat dissipation from chips to cooling systems.

· Electrical Insulation: Dielectric constant of 9.4–9.8 and breakdown voltage >2.5 kV, ensuring long-term operation in high-voltage environments.

· Mechanical Robustness: Flexural strength >330 MPa and a thermal expansion coefficient (7.7×10⁻⁶/℃) closely matching silicon chips, suitable for extreme temperatures from -55℃ to +175℃.

Ⅱ. Six Core Application Scenarios Analyzed

1. High-Power LED Lighting Systems

In stage lights, automotive headlamps, and other scenarios, aluminum oxide ceramic PCBs use 3D vertical packaging technology to directly weld LED chips onto the substrate surface, achieving:

· Enhanced Heat Dissipation: Thermal resistance of a 96% alumina substrate is only 0.31 K/W (10×10mm size), 40% lower than aluminum substrates.

· Extended Lifespan: Cree’s XLamp® series LEDs with alumina substrates show <5% light decay after 1,000 hours of aging testing.

· High-Frequency Drive Support: Dielectric loss tangent <4×10⁻⁴, stable for PWM signals above 200 MHz.

2. New Energy Vehicle Three-Electric Systems

In 800V high-voltage platforms, aluminum oxide ceramic PCBs are widely used in:

· IGBT Modules: Infineon’s FS400R07A1E3 module with DBC-processed alumina substrate supports 400A current output and a thermal cycle life >5,000 times (-40℃~125℃).

· Battery Management Systems (BMS): 99% alumina substrates have insulation resistance >10¹³ Ω·m, isolating high-voltage signals between battery packs and vehicle bodies for safety.

· Motor Controllers: Mitsubishi Materials’ gradient copper layer technology controls substrate thickness tolerance within ±10μm, improving reliability in vibration environments.

3. Industrial Automation and Power Electronics

In wind power converters, photovoltaic inverters, and other equipment, aluminum oxide ceramic PCBs with thick copper layers (100–600μm) enable:

· High Current Capacity: Copper layer resistivity 2.5×10⁻⁶ Ω·mm, supporting instantaneous currents over 1,000A.

· Corrosion Resistance: Gold-plated surfaces (>1μm thickness) resist salt fog, meeting IP67 protection requirements.

4. 5G Communication Base Stations

In millimeter-wave antenna arrays, the low dielectric loss (tanδ<0.001) of alumina substrates ensures:

· Signal Integrity: 60% lower signal transmission loss at 28 GHz compared to FR4 substrates.

· Higher Integration: DPC process supports 20μm linewidth, integrating 256 antenna units in 100mm².

5. Medical Equipment and Aerospace

In CT scanners and MRI devices, the radiation resistance (insulation resistance retention >90% under 200krad) of aluminum oxide ceramic PCBs ensures:

· Data Accuracy: Thermal expansion mismatch between silicon nitride substrates and gallium arsenide chips is only 2.3ppm/℃ in space environments, preventing signal drift.

· Lightweight Design: Substrate thickness can be reduced to 0.1mm, meeting strict weight requirements for aerospace equipment.

6. Consumer Electronics Fast Charging Modules

In 120W+ GaN fast chargers, the ultra-thin packaging capability (thickness ≤0.2mm) of alumina substrates enables:

· Higher Power Density: Combined with embedded capacitor technology (5nF/cm²), circuit board area is reduced by 30%, with power density up to 500 W/cm².

· Welding Resistance: Withstands reflow soldering at 260℃ over 10 times, suitable for mass production.

Ⅲ. Technical Comparison and Market Trends

Market Data:

· China’s alumina ceramic substrate market is projected to reach ¥1.33 billion by 2025, with a CAGR of 19.1%.

· The global ceramic substrate market will grow at a CAGR of 14.9%, reaching $4.102 billion by 2031.

Ⅳ. Manufacturing Processes and Challenges

1. DBC Process: Bonds copper foil to alumina at 800–1000℃, 30–40% cheaper than AMB but with thermal cycle life <5,000 times.

2. AMB Process: Uses active metal brazing for metallurgical bonding between copper and silicon nitride, with thermal cycle life >500,000 times—ideal for automotive-grade SiC modules.

3. DPC Process: Forms 10–50μm copper layers via sputtering and electroplating, achieving 20μm linewidth precision for high-frequency communication modules.

Technical Bottlenecks:

· Cost Control: 99% alumina substrates are 10x more expensive than FR4; scale production is needed to reduce costs.

· Process Optimization: Low-temperature sintering (adding lithium oxide additives) lowers sintering temperature from 1700℃ to 1450℃, but yield improvement is still needed.

Ⅴ. Leading Manufacturers and Products

· Infineon: FS400R07A1E3 IGBT module with alumina substrate, supporting 400A current for hybrid vehicles.

· Cree: XLamp® CXA2011 LED with 96% alumina substrate, 150 lm/W efficacy and >50,000-hour lifespan.

· Silitong: 3D 96 alumina PCB with thermal conductivity 20–200 W/m·K, 3mil linewidth for 5G base station RF modules.

Ⅵ. Future Development Directions

1. Material Innovation: AlN-SiC composite substrates (thermal conductivity >200 W/m·K) will be applied to liquid-cooled heat dissipation modules in ultra-fast chargers.

2. Process Upgrades: Nano-silver sintering technology reduces interface thermal resistance by another 30%, improving chip junction temperature stability.

3. Standardization: Chinese military standards (e.g., GJB 3336-1998) are aligning with international IPC-6012 standards, promoting industry regularization.

Conclusion: Aluminum oxide ceramic-based PCBs have become core materials in high-power electronics due to their superior thermal management and electrical performance. With the surge in new energy vehicles, 5G communications, and other industries, market demand will continue to grow. Through material innovation and process optimization, these PCBs will drive further technical breakthroughs in diverse fields.

Engineering Guide to Aluminum Oxide Ceramic-Based PCBs Material, Process, and Application Insights