Full analysis of metal core PCB technology From material properties to engineering practice guidelines

Redefining the Heat Dissipation Boundaries of Circuit Boards

I. Metal Core PCB Technology Map

1.1 Structural Deconstruction and Material Revolution

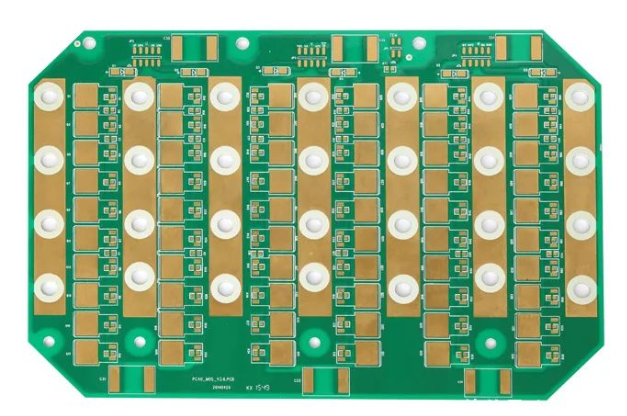

Circuit layers (1 - 10oz copper thickness): A special lamination process is used to achieve an interfacial thermal resistance of <0.05°C/W

1.2 Comparison of Four Substrate Types

Parameters | Aluminum Substrate | Copper Substrate | Iron Substrate | Composite Substrate |

Thermal Conductivity (W/mK) | 180 - 220 | 380 - 400 | 30 - 50 | 150 - 180 |

CTE (ppm/°C) | 23.6 | 17.0 | 11.7 | 14 - 18 |

Cost Index | 1.0 | 3.2 | 0.8 | 2.5 |

Typical Applications | LED Lighting | Automotive Electronics | Precision Instruments | Aerospace |

II. Key Performance Breakthrough

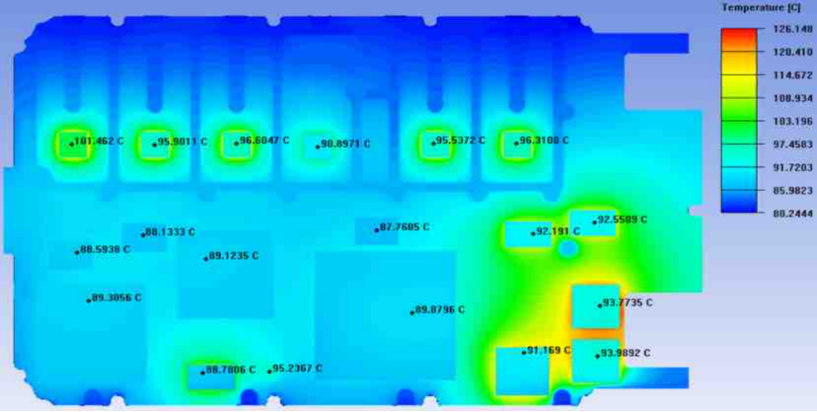

2.1 Leap in Thermal Management Dimension

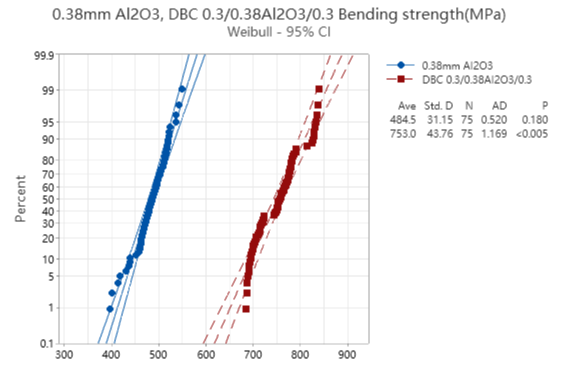

2.2 Reconstruction of Mechanical Properties

Electromagnetic shielding: The shielding effectiveness of the copper substrate at 1GHz reaches 65dB

III. Engineering Application Decision Tree

3.1 Analysis of the Selection Decision - Making Logic

The selection of Metal Core PCBs needs to follow a three - level decision - making logic of "power density - thermal stress - mechanical stress":

3.2 Golden Rules for Design

① Heat channel design: Power components must be in direct contact with the metal substrate, and the diameter of the heat - conducting holes needs to be >0.3mm.

IV. Frontier Application Case Library

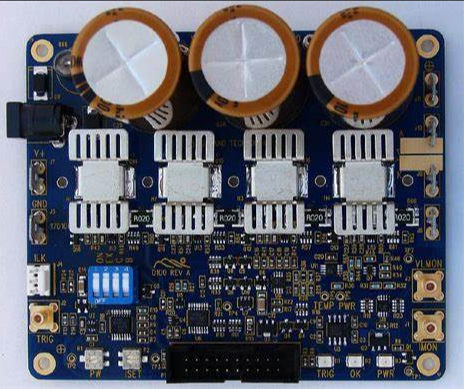

4.1 Tesla 4680 Battery BMS System

It adopts a three - layer copper substrate stacking structure:

①Substrate thickness: 2.0mm OFC copper② Insulating layer: 125μm AlN - filled resin③ It realizes a 96 - channel temperature acquisition system, and the thermal gradient is controlled within ±1.5°C.

4.2 Industrial Laser Driver Module

① Substrate material: 3mm copper - molybdenum alloy (thermal conductivity 220W/mK, CTE 7.2ppm/°C)

V. Technology Evolution Roadmap

1.Nanoscale interface engineering: The graphene coating reduces the interfacial thermal resistance to 0.01°C/W.

2.Heterogeneous metal composites: Copper - aluminum composite substrates achieve directional heat conduction (380W/mK longitudinally, <50W/mK laterally).

3.Intelligent heat sink technology: The integration of phase - change materials (PCM) and Metal substrates increases the thermal buffer capacity by 400%.

Conclusion: Redefining the Thermal Boundaries of Electronic Systems

When a leading photovoltaic inverter manufacturer optimized the thickness of the aluminum substrate from 3.0mm to 1.6mm, the system power density increased by 37%, and the MTBF (Mean Time Between Failures) jumped from 50,000 hours to 80,000 hours. This verifies that Metal Core PCBs are not only heat dissipation components but also the core carriers for reconstructing the reliability of electronic systems. With the popularization of 5G millimeter - wave and silicon carbide devices, metal substrates are breaking through traditional cognitive boundaries and developing towards multi - functional integration.

(Data sources of this article: IPC - 6012D standard, Bergquist technical white paper, test report of Nippon Chemical Industrial Co., Ltd.)